Products

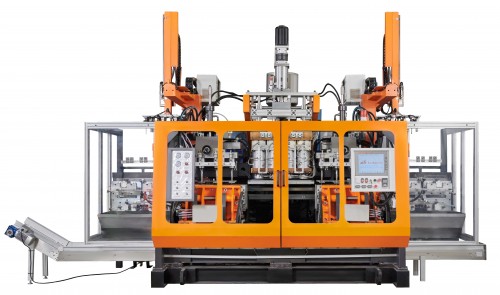

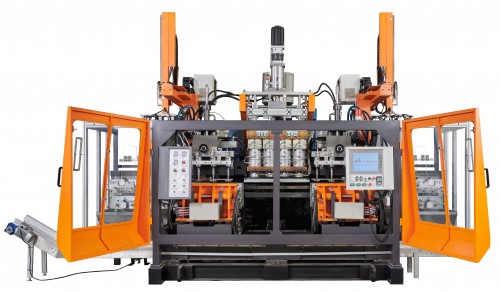

SL2-L2X4-1A

Features: A die head of German design for convenient adjustment, quick material-changing and safer operation. Servo-balance system for the die head, ensuring precise and powerful lifting and descending of it. Blow pin frame of linear-guide rail and RCI system for higher precision and less friction. Rapid cooling installation which cools down through heat exchange between hot and cold wind, reducing cooling time by 30%-40% A clamping plate controlled by an electric scale for higher precision and quicker movement. Optimized layout of tubes, avoiding leakage of water and oil.

Description:

The brand-new Athlon EBM machine, designed by our German engineer, is distinguished from its kind. With a new clamping device providing strong forces, the machine can move steadily and fast. Secondly, the rapid cooling installation (RCI) system and fast mold-changing system allow the machine to produce with less time and higher productivity. Also, its safety design, which ensures the protection for users, is highly user-friendly.

Single/Double Station

Single/Double/Triple/Quadruple...8 Head

Production Volume:2ml~30L Multi layers: Co-Extrusion 1-6 Layers

Multi cavities: 1~8 cavities

Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion Material

Features

A die head of German design for convenient adjustment, quick material-changing and safer operation

Servo-balance system for the die head, ensuring precise and powerful lifting and descending of it.

Blow pin frame of linear-guide rail and RCI system for higher precision and less friction.

Rapid cooling installation which cools down through heat exchange between hot and cold wind, reducing cooling time by 30%-40%

A clamping plate controlled by an electric scale for higher precision and quicker movement.

Optimized layout of tubes, avoiding leakage of water and oil.