Leshan

About Us

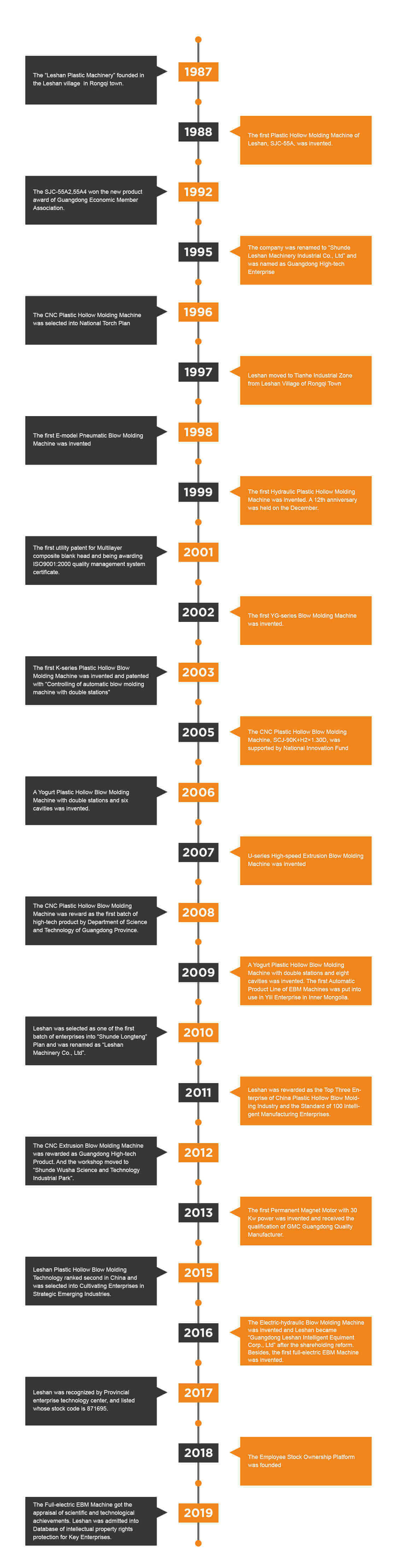

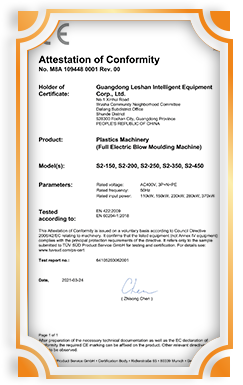

Guangdong Leshan Intelligent Equipment Corp., Ltd.

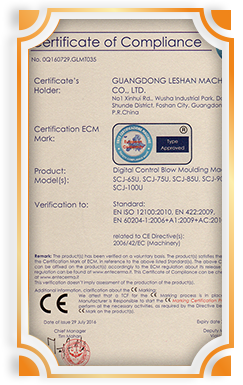

The top three companies of EBM machines industry 38 years experience in development and manufacturing of EBM machines, molds, and services Founded in August 1995, Leshan Intelligent Equipment is an innovative company of mechanic design, R&D and production, sales, and after-sales services, with a well-developed chain and core competencies of the extrusion blow molding industry. Along with a concept of “Better quality, greater efficiency”, over 380 employees of Leshan devote their efforts to manufacture EBM machines of excellent quality and provide services of great pleasure.