Understanding the Components of a Full Electric Blow Molding Machine

Understanding the Components of a Full Electric Blow Molding Machine

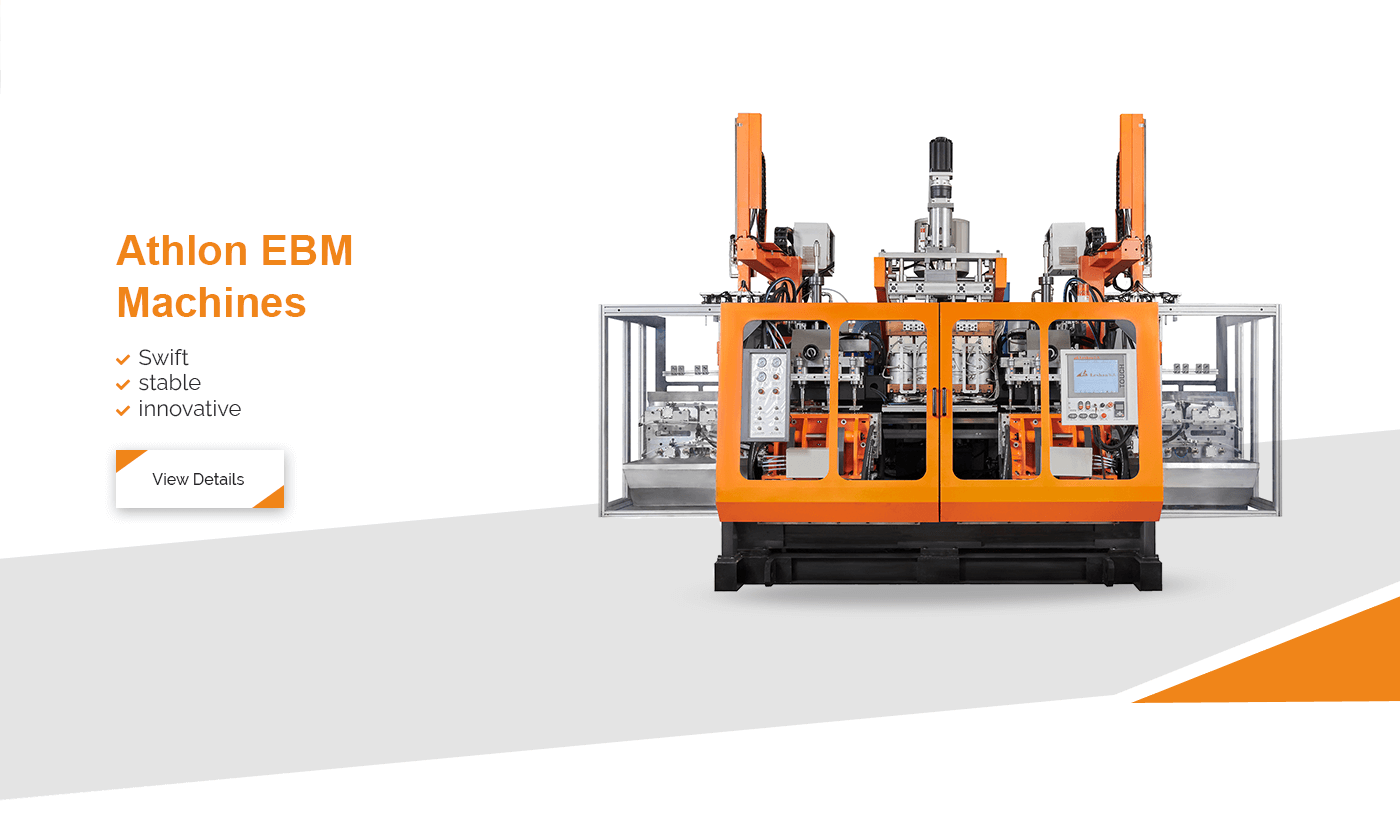

Blow molding machines have revolutionized the way plastic products are manufactured, providing precision, efficiency, and flexibility. Among the various types of blow molding machines, the full electric blow molding machine stands out as a cutting-edge innovation. Leshan, a leading blow molding machine manufacturer, has been at the forefront of developing and supplying high-quality full electric blow molding machines to industries worldwide. This article delves deep into the components of a full electric blow molding machine, highlighting how they work together to produce high-quality plastic products.

What is a Full Electric Blow Molding Machine?

A full electric blow molding machine is a type of equipment used to produce hollow plastic products through the blow molding process. Unlike traditional hydraulic or pneumatic machines, full electric blow molding machines rely entirely on electric servo motors for their operations. This design offers numerous advantages, including higher energy efficiency, improved precision, reduced maintenance requirements, and a cleaner production environment.

Leshan, as a trusted name in the blow molding industry, has engineered its full electric blow molding machines to cater to diverse industrial needs. Their machines are widely used in producing items such as bottles, containers, automotive parts, and industrial packaging solutions.

Key Components of a Full Electric Blow Molding Machine

Understanding the components of a full electric blow molding machine is essential to appreciate its functionality and advantages. Below is a detailed breakdown of the critical components that make up this advanced machinery:

1. Electric Servo Motors

Electric servo motors are the heart of a full electric blow molding machine. These motors replace traditional hydraulic systems, offering precise control over movements such as clamping, injection, and ejection. Leshan integrates high-performance servo motors into its machines to ensure energy efficiency and accuracy during the production process.

The use of servo motors not only reduces energy consumption but also minimizes noise levels and eliminates the risk of hydraulic oil leakage, making the machine more environmentally friendly.

2. Extrusion System

The extrusion system is responsible for melting and forming the plastic material into a parison (a hollow tube). Leshan's extrusion systems are designed for optimal plasticizing and material homogeneity. Key components of the extrusion system include:

- Barrel and Screw: These components work together to heat and mix the plastic material uniformly.

- Extrusion Motor: The motor drives the screw, ensuring consistent material flow.

- Temperature Control System: This system maintains the ideal temperature for plastic melting and extrusion.

3. Parison Die Head

The die head is a crucial component that shapes the molten plastic into a parison. Leshan's die head designs ensure uniform wall thickness and precise control over the parison's dimensions. This accuracy is vital for producing high-quality end products with consistent performance.

4. Clamping Unit

The clamping unit holds the mold in place during the blow molding process. In full electric blow molding machines, the clamping force is generated by electric servo motors, providing precise and consistent clamping pressure. Leshan's clamping units are engineered for durability and reliability, ensuring seamless mold operations.

5. Mold

The mold is where the final product takes shape. It consists of two halves that enclose the parison during the blow molding process. Leshan offers customizable mold solutions to meet the specific requirements of different industries. The molds are designed for easy installation and maintenance, ensuring minimal downtime.

6. Blow Pin and Air System

The blow pin is inserted into the parison to introduce pressurized air, which inflates the parison to conform to the mold's shape. Leshan's air systems are designed for precise air pressure control, ensuring uniform product expansion and minimal defects.

7. Cooling System

Once the plastic product is formed, it needs to be cooled to solidify its shape. Leshan's full electric blow molding machines feature advanced cooling systems that ensure efficient heat dissipation. Proper cooling is essential for maintaining product quality and preventing deformation.

8. Control System

The control system serves as the brain of the blow molding machine. Leshan equips its machines with state-of-the-art PLC (Programmable Logic Controller) systems and user-friendly HMI (Human-Machine Interface) panels. These systems allow operators to monitor and control various parameters, such as temperature, pressure, and cycle time, with ease.

9. Ejection System

After the product is formed and cooled, the ejection system removes it from the mold. Leshan's full electric blow molding machines use servo-driven ejection systems for precise and efficient product removal, reducing the risk of damage or deformation.

10. Safety Features

Safety is a top priority in industrial machinery. Leshan incorporates multiple safety features into its full electric blow molding machines, such as emergency stop buttons, safety interlocks, and protective enclosures. These features ensure safe operation and protect operators from potential hazards.

Advantages of Full Electric Blow Molding Machines

Full electric blow molding machines offer several benefits over traditional hydraulic and pneumatic machines. Some of the key advantages include:

- Energy Efficiency: Electric servo motors consume significantly less energy compared to hydraulic systems.

- Precision: The use of servo motors ensures accurate control over all machine movements, resulting in high-quality products.

- Reduced Maintenance: Electric systems require less maintenance than hydraulic systems, reducing downtime and operational costs.

- Environmentally Friendly: The absence of hydraulic oil eliminates the risk of leaks and contamination, promoting a cleaner production environment.

- Quiet Operation: Electric machines operate with minimal noise, improving workplace conditions.

Applications of Leshan Full Electric Blow Molding Machines

Leshan's full electric blow molding machines are versatile and can be used in various industries, including:

- Packaging: Production of bottles, jars, and containers for food, beverages, cosmetics, and pharmaceuticals.

- Automotive: Manufacturing of fuel tanks, air ducts, and other automotive components.

- Industrial: Creation of drums, barrels, and other large-capacity containers.

- Consumer Goods: Production of toys, household items, and recreational products.

Conclusion

Leshan, as a trusted blow molding machine manufacturer, continues to innovate and deliver high-performance full electric blow molding machines to meet the evolving needs of industries worldwide. By understanding the components and advantages of these machines, businesses can make informed decisions to enhance their production capabilities and achieve superior product quality.

Whether you are in the packaging, automotive, or industrial sector, Leshan's full electric blow molding machines are designed to provide reliability, efficiency, and precision. Investing in this advanced technology is a step toward sustainable and efficient manufacturing practices.

Tags:All-Electric Blow Molding Machines Exporter Presents A New Addition,Cleaner And Easy To Maintain Hdpe Hydraulic Plastic Blow Molding Machine China,blow molding machine,blow molding machine manufacturer