The Role of EBM Machine in Modern Manufacturing

The Role of EBM Machine in Modern Manufacturing

In today’s rapidly evolving manufacturing industry, efficiency and precision are paramount. Among the many innovations shaping the landscape, Extrusion Blow Molding (EBM) machines have emerged as a crucial technology. These machines have revolutionized the production of hollow plastic parts and containers, enabling manufacturers to meet growing demands for quality, scalability, and cost-effectiveness. Leshan, a renowned blow molding machine manufacturer, has been at the forefront of this revolution, delivering cutting-edge EBM solutions to industries worldwide. This article delves into the role of EBM machines in modern manufacturing, with a focus on Leshan’s contributions to this transformative technology.

Understanding Extrusion Blow Molding (EBM)

Extrusion Blow Molding (EBM) is a manufacturing process used to produce hollow plastic components. The process involves melting plastic resin and extruding it into a hollow tube, known as a parison. The parison is then enclosed in a mold, and air is blown into it to inflate the plastic, taking the shape of the mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished product is ejected. This process is ideal for creating items such as bottles, containers, automotive parts, and industrial components.

The Advantages of EBM Machines

EBM machines offer several advantages that make them indispensable in modern manufacturing:

- Versatility: EBM machines can produce a wide range of products, from small bottles to large industrial containers, making them suitable for various industries.

- Cost-Effectiveness: The process minimizes material wastage and reduces production costs, enabling manufacturers to achieve higher profitability.

- High Efficiency: EBM machines are designed for high-speed production, allowing manufacturers to meet large-scale demands without compromising quality.

- Design Flexibility: The technology supports complex shapes and intricate designs, providing manufacturers with the freedom to innovate and differentiate their products.

- Durability: Products created using EBM machines are known for their strength and durability, ensuring long-lasting performance in various applications.

Leshan: A Leader in Blow Molding Technology

As a leading blow molding machine manufacturer, Leshan has played a pivotal role in advancing EBM technology. With decades of experience and a commitment to innovation, the company has established itself as a trusted partner for manufacturers across the globe. Leshan’s EBM machines are renowned for their reliability, precision, and state-of-the-art features, making them the preferred choice for businesses seeking to enhance their production capabilities.

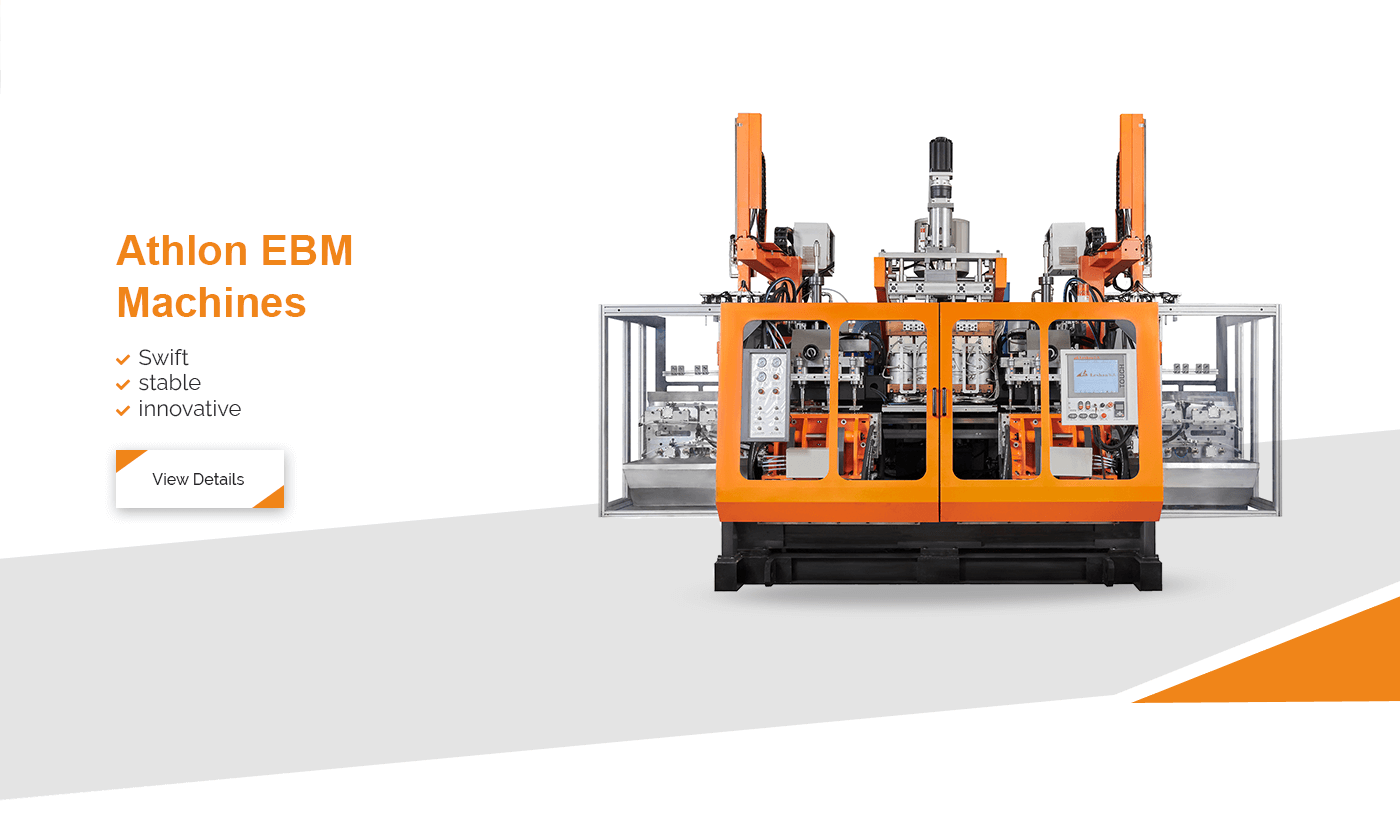

Key Features of Leshan’s EBM Machines

Leshan’s EBM machines are designed to meet the diverse needs of modern manufacturers. Some of the standout features include:

- Advanced Control Systems: Leshan’s machines are equipped with intuitive control systems that ensure precise operation and seamless integration into existing production lines.

- Energy Efficiency: The company prioritizes sustainability, incorporating energy-saving technologies to reduce environmental impact and operational costs.

- Customizable Solutions: Leshan offers tailored EBM machines to meet specific production requirements, ensuring optimal performance and efficiency.

- Robust Construction: Built with high-quality materials, Leshan’s machines are engineered for durability and long-term reliability.

- Comprehensive Support: Leshan provides extensive technical support, training, and maintenance services to help customers maximize the value of their investment.

Applications of EBM Machines in Various Industries

EBM machines are used across a wide range of industries, demonstrating their versatility and importance in modern manufacturing:

1. Packaging Industry

The packaging industry is one of the largest consumers of EBM technology. Leshan’s machines are used to produce plastic bottles, jars, and containers for beverages, cosmetics, pharmaceuticals, and household products. The ability to create lightweight, durable, and aesthetically appealing packaging solutions has made EBM machines a cornerstone of this industry.

2. Automotive Sector

In the automotive sector, EBM machines are utilized to manufacture fuel tanks, air ducts, and other critical components. Leshan’s advanced machines ensure high precision and durability, meeting the stringent quality standards required in this industry. The lightweight nature of plastic components also contributes to improved fuel efficiency and reduced emissions in vehicles.

3. Industrial Applications

EBM technology is widely used in industrial applications to produce large containers, drums, and storage tanks. Leshan’s machines are capable of handling high-volume production while maintaining consistent quality, making them an ideal choice for industrial manufacturers.

4. Consumer Goods

From toys to household items, EBM machines enable the production of a variety of consumer goods. Leshan’s machines support complex designs and vibrant colors, allowing manufacturers to create appealing products that resonate with consumers.

The Future of EBM Technology

As industries continue to evolve, the demand for innovative and sustainable manufacturing solutions is on the rise. EBM technology is expected to play a significant role in shaping the future of manufacturing, driven by advancements in materials, automation, and digitalization. Leshan is committed to staying ahead of the curve, investing in research and development to deliver next-generation EBM machines that meet the changing needs of its customers.

Trends Driving the Growth of EBM Technology

Several trends are influencing the growth and adoption of EBM technology:

- Sustainability: The focus on reducing plastic waste and promoting recycling is driving the development of eco-friendly materials and processes in EBM technology.

- Automation: The integration of automation and robotics is enhancing the efficiency and accuracy of EBM machines, enabling manufacturers to achieve higher productivity.

- Smart Manufacturing: The adoption of Industry 4.0 technologies, such as IoT and AI, is enabling real-time monitoring and optimization of EBM processes.

- Customization: The growing demand for personalized products is encouraging manufacturers to leverage EBM technology for small-batch production and unique designs.

Conclusion

Extrusion Blow Molding (EBM) machines have become an integral part of modern manufacturing, offering unparalleled advantages in terms of efficiency, versatility, and cost-effectiveness. Leshan, as a leading blow molding machine manufacturer, has been instrumental in advancing this technology, providing innovative solutions that empower industries to thrive in a competitive market. With a focus on quality, sustainability, and customer satisfaction, Leshan continues to set new benchmarks in the field of EBM technology, shaping the future of manufacturing for years to come.

Whether it’s producing lightweight packaging, durable automotive components, or intricate consumer goods, EBM machines are revolutionizing the way products are made. As industries embrace the potential of this transformative technology, companies like Leshan are paving the way for a more efficient, sustainable, and innovative manufacturing landscape.