Talk About the Latest Innovations in Automatic Blow Molding Machines

Talk About the Latest Innovations in Automatic Blow Molding Machines

In the dynamic world of manufacturing, the need for efficiency, precision, and sustainability is ever-increasing. Blow molding, a process used to create hollow plastic parts, has seen significant advancements in recent years. Among the leaders in this field is Leshan, a renowned company specializing in the production of automatic blow molding machines. This article delves into the latest innovations in automatic blow molding machines, with a particular focus on the contributions and advancements made by Leshan.

Understanding Blow Molding

Blow molding is a manufacturing process used to produce hollow objects by inflating a heated plastic tube until it fills a mold and forms the desired shape. This technique is used extensively in the production of items such as bottles, containers, and automotive parts. The process is divided into three main types: extrusion blow molding, injection blow molding, and injection stretch blow molding. Each type has its specific applications and advantages, making blow molding a versatile and essential process in modern manufacturing.

The Role of Automation in Blow Molding

Automation has revolutionized the blow molding industry, enhancing productivity, reducing human error, and ensuring consistent quality. Automatic blow molding machines are designed to perform the entire process with minimal human intervention, from feeding the raw material to ejecting the finished product. These machines are equipped with advanced sensors and control systems that monitor and adjust the process parameters in real-time, ensuring optimal performance and product quality.

Leshan: A Leader in Blow Molding Innovation

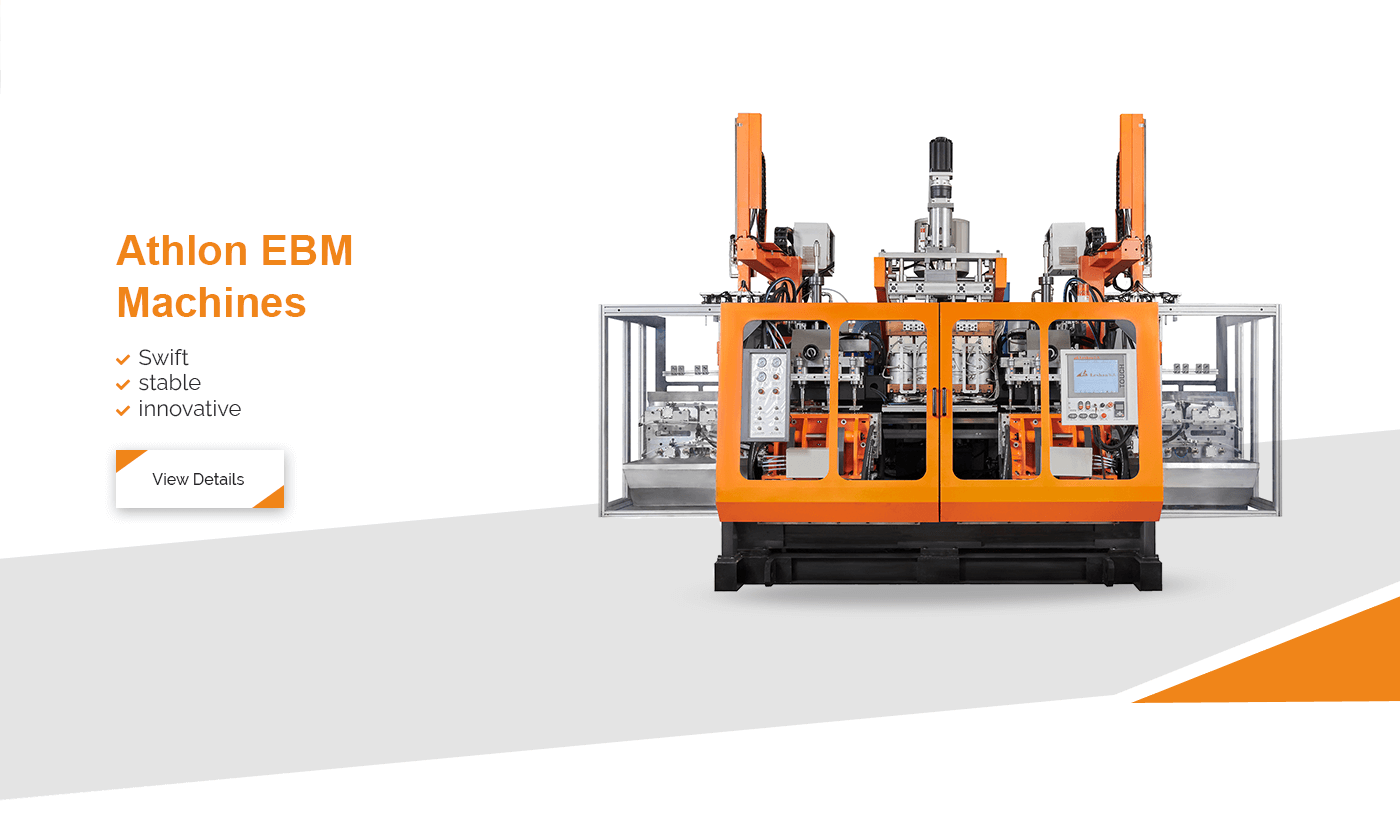

Leshan has established itself as a pioneer in the blow molding industry, consistently pushing the boundaries of innovation. The company's automatic blow molding machines are renowned for their reliability, efficiency, and cutting-edge technology. Leshan's commitment to research and development has resulted in numerous breakthroughs that have set new standards in the industry.

Key Innovations by Leshan

1. Energy Efficiency

One of the most significant advancements in Leshan's blow molding machines is their energy efficiency. The company has developed machines that consume significantly less energy compared to traditional models. This is achieved through the use of high-efficiency motors, improved insulation, and advanced control systems that optimize energy consumption during the molding process. Leshan's focus on sustainability not only reduces operational costs but also minimizes the environmental impact of manufacturing.

2. Enhanced Precision and Control

Precision is crucial in blow molding, as even minor deviations can lead to defects in the final product. Leshan has integrated state-of-the-art control systems into their machines, allowing for precise monitoring and adjustment of process parameters such as temperature, pressure, and mold alignment. These systems use advanced algorithms and machine learning techniques to predict and correct potential issues before they affect production, ensuring high-quality output.

3. Improved Material Utilization

Material waste is a significant concern in blow molding, both from an economic and environmental perspective. Leshan's machines are designed to maximize material utilization by minimizing waste during the molding process. This is achieved through precise control of the parison (the plastic tube that is inflated) and innovative mold designs that reduce excess material. As a result, manufacturers can produce more products with the same amount of raw material, leading to cost savings and reduced environmental impact.

4. Faster Production Cycles

In today's fast-paced market, the ability to produce high volumes of products quickly is a competitive advantage. Leshan's automatic blow molding machines are engineered for speed, with innovations that reduce cycle times without compromising quality. These machines incorporate rapid heating and cooling systems, optimized mold designs, and efficient material handling processes, enabling manufacturers to meet high demand with ease.

5. User-Friendly Interface and Maintenance

Complex machinery often requires skilled operators and extensive maintenance, which can be costly and time-consuming. Leshan has addressed this challenge by designing user-friendly interfaces for their machines, making them accessible to operators with varying levels of expertise. The machines are equipped with intuitive touchscreens and user guides, simplifying operation and troubleshooting. Additionally, Leshan's machines are designed for easy maintenance, with modular components and accessible parts that reduce downtime and maintenance costs.

Applications of Leshan's Blow Molding Machines

Leshan's automatic blow molding machines are used across various industries, thanks to their versatility and adaptability. Some of the key applications include:

- Packaging Industry: Leshan's machines are ideal for producing bottles, containers, and jars used in the food, beverage, and pharmaceutical industries. Their ability to create lightweight, durable, and hygienic packaging solutions makes them a preferred choice for manufacturers.

- Automotive Industry: The automotive sector relies on blow molding for producing components such as fuel tanks, air ducts, and reservoirs. Leshan's machines offer the precision and strength required for these critical parts.

- Consumer Goods: From toys to household items, Leshan's machines are used to manufacture a wide range of consumer goods. Their flexibility in handling different materials and shapes makes them suitable for diverse applications.

- Industrial Applications: Leshan's machines are also used in industrial applications, producing items such as drums, tanks, and large containers. Their robust construction and efficiency make them suitable for heavy-duty manufacturing.

The Future of Blow Molding with Leshan

As the demand for efficient, sustainable, and high-quality manufacturing processes continues to grow, Leshan is poised to lead the blow molding industry into the future. The company's ongoing investment in research and development ensures that their machines remain at the forefront of innovation, meeting the evolving needs of manufacturers worldwide.

Looking ahead, Leshan is exploring new materials and technologies that could further enhance the capabilities of their blow molding machines. This includes the development of machines that can process biodegradable and recycled materials, aligning with global efforts to reduce plastic waste and promote sustainability.

Moreover, Leshan is leveraging the power of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), to create smarter, more connected machines. These advancements will enable real-time monitoring and predictive maintenance, further improving efficiency and reducing downtime.

Conclusion

Leshan's commitment to innovation and excellence has solidified its position as a leader in the blow molding industry. The company's automatic blow molding machines are a testament to their dedication to quality, efficiency, and sustainability. As Leshan continues to push the boundaries of what's possible, manufacturers can look forward to even more advanced solutions that meet the demands of today's competitive market.

In conclusion, the latest innovations in automatic blow molding machines, as exemplified by Leshan, are transforming the manufacturing landscape. With a focus on energy efficiency, precision, material utilization, speed, and user-friendliness, Leshan is setting new standards for the industry. As technology continues to evolve, Leshan's machines will undoubtedly play a crucial role in shaping the future of manufacturing.