Price of Pesticide Bottle Blow Molding Machine

Price of Pesticide Bottle Blow Molding Machine

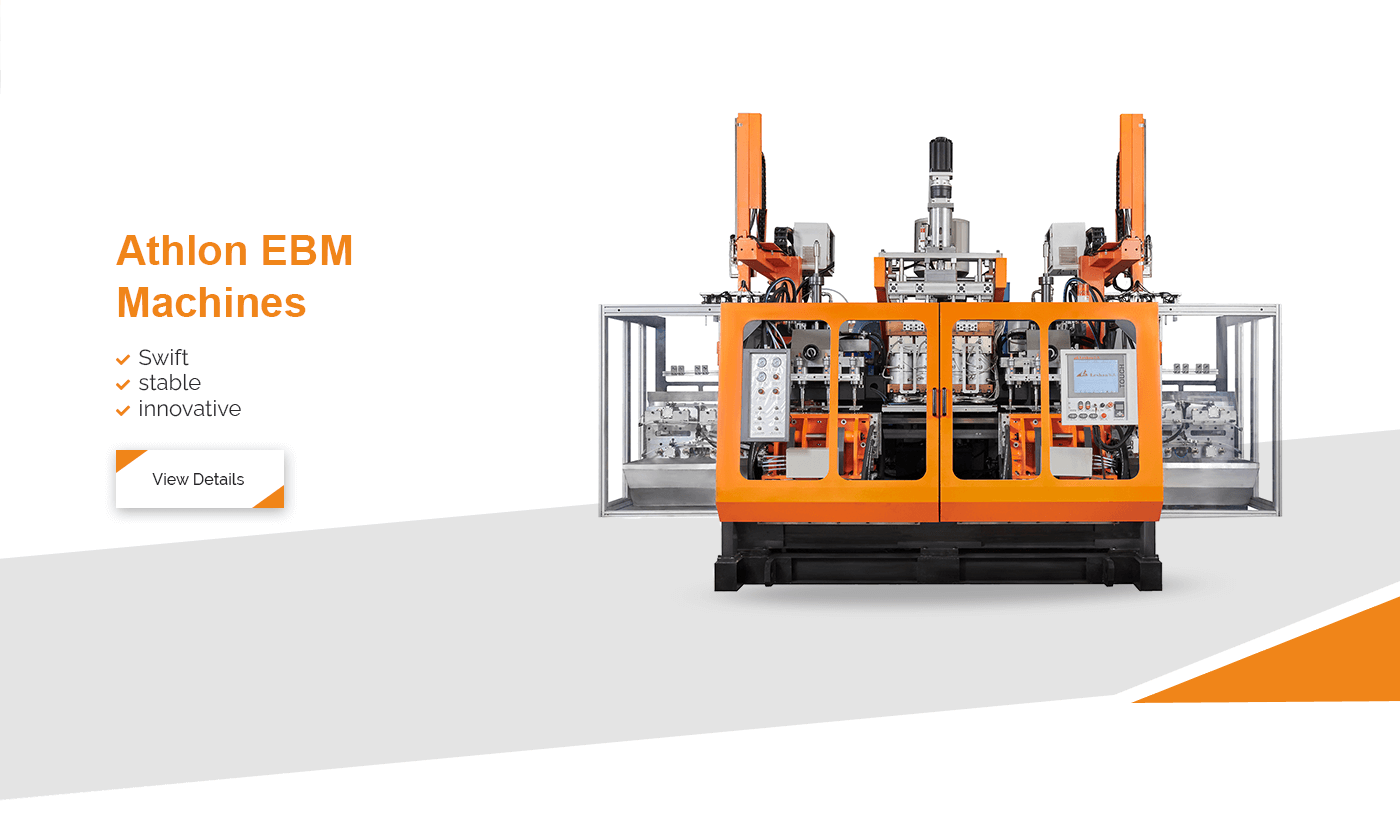

As the demand for customised pesticide bottles grows, manufacturers are seeking high-quality and cost-efficient solutions for production. A pesticide bottle blow molding machine is a critical piece of equipment in this process, offering precision, efficiency, and scalability. Leshan, a leading blow molding machine manufacturer, provides expert insights into pricing factors and machine selection to help you make an informed decision.

What is a Pesticide Bottle Blow Molding Machine?

Blow molding machines are designed to manufacture hollow plastic bottles by inflating molten plastic into a mould. For pesticide bottles, the machine must meet stringent quality and safety standards, ensuring the bottles are durable, leak-proof, and compatible with chemical storage.

Key Features of Leshan’s Blow Molding Machines for Pesticide Bottles

- Precision Moulding: Advanced mould designs ensure uniform wall thickness and durability.

- Customisation: Options to produce bottles of various sizes and shapes to meet diverse market demands.

- Energy Efficiency: Optimised heating systems reduce energy consumption, making production cost-effective.

- High Production Capacity: Machines cater to small-scale and large-scale production needs.

- Durability and Low Maintenance: Robust construction ensures long-term reliability.

Factors Affecting the Price of a Pesticide Bottle Blow Molding Machine

Several variables influence the cost of these machines:

1. Type of Blow Molding Technology

- Extrusion Blow Molding (EBM): Ideal for large-volume bottles; moderately priced.

- Injection Stretch Blow Molding (ISBM): Best for lightweight and complex designs; higher initial cost but offers premium quality.

- Injection Blow Molding (IBM): Suitable for small bottles; compact and cost-efficient.

2. Machine Specifications

The size, production speed, and degree of automation significantly impact the price. A fully automated machine costs more but reduces labour expenses in the long run.

3. Material Compatibility

Machines capable of handling diverse plastics like HDPE, LDPE, and PET may have a higher price tag. Leshan offers multi-material compatibility, ensuring flexibility in production.

4. Customisation Requirements

Special moulds and additional features (e.g., in-mould labelling) increase the cost but provide added value.

5. After-Sales Support

Leshan’s comprehensive after-sales services, including installation, training, and maintenance, add value to the investment.

Typical Price Range of Pesticide Bottle Blow Molding Machines

Based on industry standards, here’s a rough estimate of prices for various categories:

- Small-Scale Manual Machines: $8,000–$15,000

- Semi-Automatic Machines: $20,000–$50,000

- Fully Automatic High-Speed Machines: $80,000–$200,000

Note: These are indicative figures; actual costs depend on your specific requirements and configuration.

Why Choose Leshan for Your Pesticide Bottle Blow Molding Needs?

As a trusted blow molding machine manufacturer, Leshan has a proven track record of delivering high-quality machines to businesses worldwide. Here’s what sets us apart:

- Customised Solutions: Tailored machines to fit your unique production needs.

- Advanced Technology: Cutting-edge blow molding techniques ensure superior results.

- Competitive Pricing: Affordable solutions without compromising on quality.

- Global Support: Comprehensive assistance, from consultation to after-sales services.

- Eco-Friendly Designs: Machines engineered to reduce plastic waste and energy consumption.

FAQs About Pesticide Bottle Blow Molding Machines

1. Can Leshan’s machines produce bottles of varying capacities?

Yes, our machines are designed to manufacture pesticide bottles in a wide range of capacities, from 100 ml to 5 litres.

2. Are the machines compatible with different plastic materials?

Absolutely. Leshan machines support multiple plastic types, including PET, HDPE, and LDPE, ensuring versatility.

3. How long does installation take?

Installation typically takes 1–2 weeks, depending on the machine complexity. Leshan’s team ensures a smooth setup process.

Final Thoughts

Investing in a pesticide bottle blow molding machine is a significant decision that impacts your production efficiency and profitability. By choosing Leshan, you gain access to state-of-the-art technology, exceptional support, and competitive pricing.

Contact Leshan today for a customised quote and discover how we can revolutionise your manufacturing process.