Optimizing Production with Stretch Blow Molding: Advanced Blow Molding Machine

Optimizing Production with Stretch Blow Molding: Advanced Blow Molding Machine

Leshan, a leading blow molding machine manufacturer, is dedicated to providing state-of-the-art solutions for the manufacturing industry. This comprehensive article explores the advantages of stretch blow molding, highlighting how Leshan's advanced blow molding Machine optimize production processes. By incorporating our expertise in OEM/ODM services, R&D, and innovative design, we ensure superior quality and efficiency in every project.

What is Stretch Blow Molding?

Stretch blow molding is a manufacturing process used to create hollow plastic containers, such as bottles and jars, by stretching and blowing a preform into a mold. This process enhances the material's strength and clarity, making it ideal for producing high-quality, durable plastic products.

The Stretch Blow Molding Process

1. Preform Production

The process begins with the injection molding of preforms, which are small, thick plastic tubes that resemble test tubes. These preforms are made from thermoplastics like PET (Polyethylene Terephthalate), known for its strength and clarity.

2. Heating

The preforms are then heated to a temperature that allows them to be stretched and molded without losing their structural integrity. This heating process is precisely controlled to ensure uniformity.

3. Stretching and Blowing

Once heated, the preform is placed in a blow molding machine. The machine stretches the preform both axially (lengthwise) and radially (sideways) using a stretch rod and compressed air. This dual stretching process ensures that the material is evenly distributed, enhancing the strength and clarity of the final product.

4. Cooling and Ejection

After the preform has been stretched and blown into the desired shape, it is cooled within the mold to retain its shape. The finished product is then ejected from the mold, ready for any necessary secondary operations.

Benefits of Stretch Blow Molding

1. Superior Material Properties

Stretch blow molding significantly enhances the material properties of the final product. The biaxial stretching process increases the strength, clarity, and impact resistance of the plastic, making it suitable for high-quality applications.

2. Efficient Production

Leshan's advanced blow molding Machine optimize the production process, allowing for high-speed manufacturing with minimal waste. This efficiency translates to lower production costs and faster turnaround times for large-scale projects.

3. Versatility in Design

Stretch blow molding offers exceptional versatility in design, enabling the production of complex shapes and sizes. This flexibility allows manufacturers to create custom products that meet specific requirements, making it ideal for OEM/ODM services.

4. Consistency and Precision

The precision control of the stretching and blowing process ensures that each product is consistent in quality and dimensions. This reliability is crucial for industries that require uniformity in their products, such as the beverage, pharmaceutical, and personal care sectors.

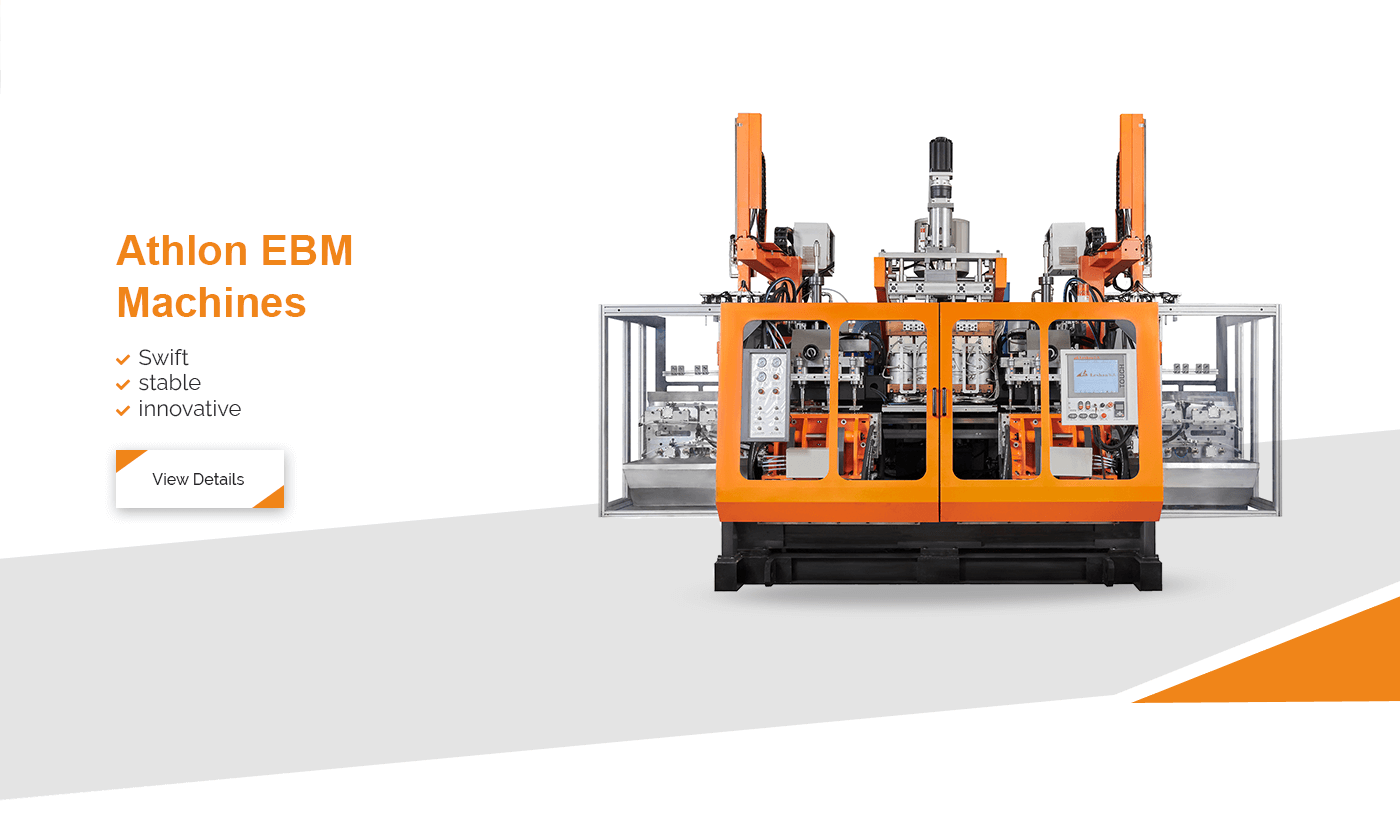

Leshan’s Advanced Blow Molding Machine

As a premier blow molding machine manufacturer, Leshan is committed to delivering innovative solutions that meet the highest standards of quality and performance. Our advanced blow molding Machine are designed to optimize the stretch blow molding process, providing numerous benefits for our clients.

Advanced Manufacturing Techniques

Leshan utilizes cutting-edge manufacturing techniques to produce blow molding Machine that deliver exceptional performance and reliability. Our Machine are designed to handle a wide range of materials and applications, ensuring versatility and adaptability in various industries.

Comprehensive OEM/ODM Services

We offer comprehensive OEM/ODM services, working closely with clients to develop custom solutions that meet their unique needs. Our expertise in design and manufacturing allows us to create tailored products that align with specific project requirements.

Dedicated R&D and Innovative Design

At Leshan, we prioritize research and development to stay at the forefront of blow molding technology. Our dedicated R&D team continuously explores new materials, processes, and designs to enhance the capabilities of our Machine. This commitment to innovation ensures that we deliver the most advanced and efficient solutions to our clients.

Rigorous Quality Control

Quality is at the core of everything we do at Leshan. We implement rigorous quality control measures throughout the manufacturing process to ensure that every machine meets the highest standards of excellence. Our commitment to quality guarantees reliable and durable products for our clients.

Applications of Leshan’s Stretch Blow Molding Machine

Beverage Industry

In the beverage industry, stretch blow molding is widely used to produce high-quality PET bottles for water, soda, juices, and other drinks. Leshan's advanced Machine ensure that these bottles are strong, clear, and consistent in quality, meeting the demands of both manufacturers and consumers.

Pharmaceutical Industry

For the pharmaceutical industry, stretch blow molding provides the precision and consistency needed to produce medical-grade containers. These containers must meet stringent safety and quality standards, and Leshan's Machine are designed to deliver exceptional performance in this critical sector.

Personal Care Products

Stretch blow molding is ideal for producing containers for personal care products, such as shampoos, lotions, and cosmetics. Leshan's Machine offer the flexibility to create custom designs that enhance the appeal and functionality of these products.

Industrial Applications

Leshan's stretch blow molding Machine are also used in various industrial applications, including the production of containers for chemicals, cleaning agents, and other industrial fluids. The durability and reliability of our Machine ensure that these containers meet the rigorous demands of industrial use.

Stretch blow molding is a highly efficient and versatile manufacturing process that offers numerous benefits for producing high-quality plastic products. As a leading blow molding machine manufacturer, Leshan is dedicated to providing advanced solutions that optimize production processes and enhance product quality. With our expertise in manufacturing, OEM/ODM services, R&D, and innovative design, we deliver superior blow molding Machine that meet the diverse needs of our clients. Contact us today to learn more about our stretch blow molding Machine and how we can help you achieve your manufacturing goals.

Tags: All-Electric Blow Molding Machines,Hdpe Hydraulic Plastic Blow Molding Machine,High-Power EBM Complete Machine,Automa Blow Molding Machine Manufa