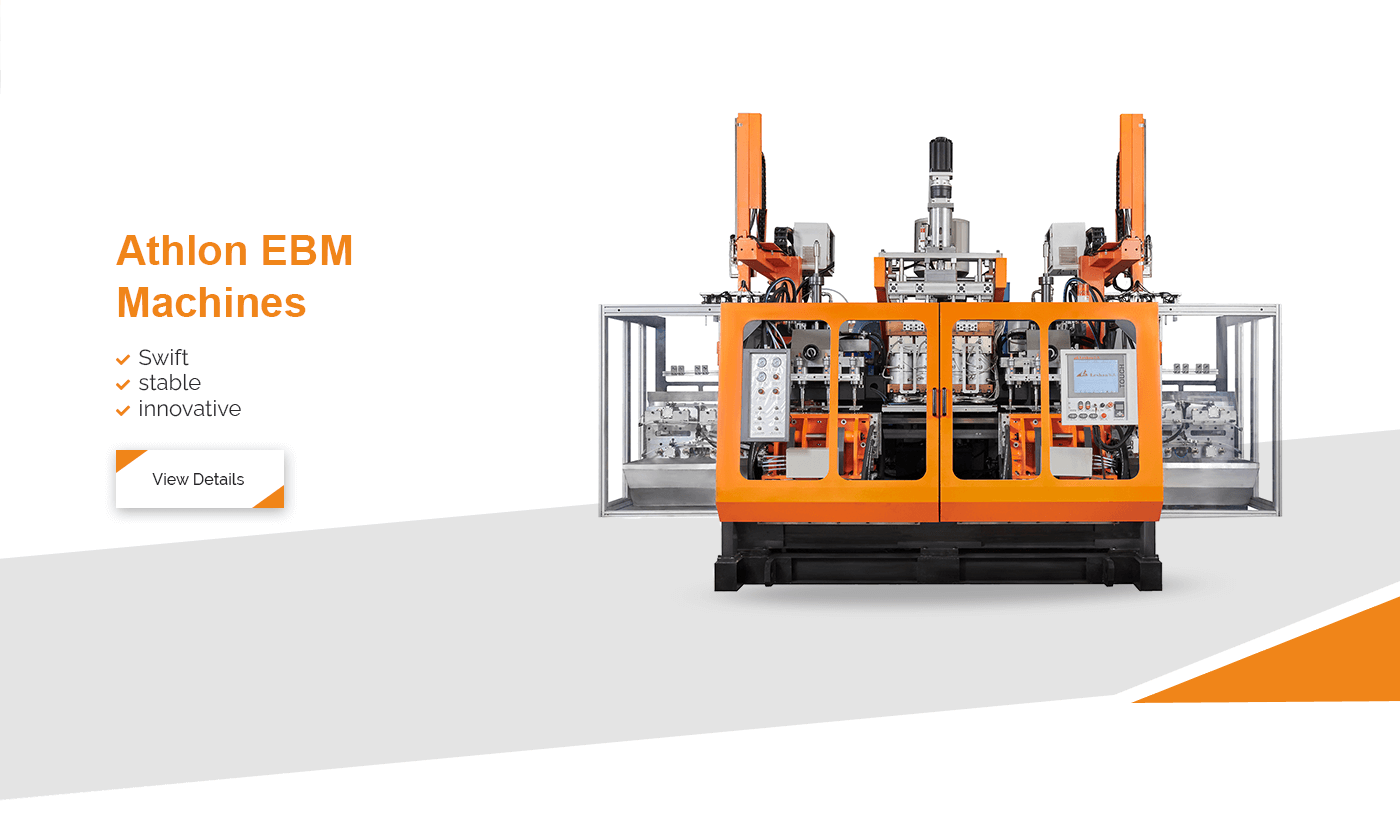

Innovative Extrusion Blow Molding Machine for Custom Solutions

Innovative Extrusion Blow Molding Machine for Custom Solutions

In the world of plastics manufacturing, the demand for customized solutions is ever-increasing. Companies are constantly on the lookout for technologies that can offer flexibility, efficiency, and precision. Leshan, a leading blow molding machine manufacturer, has risen to this challenge by developing an innovative extrusion blow molding machine that caters to the diverse needs of its clients.

About Leshan

Leshan, established in the early 2000s, has carved a niche for itself in the blow molding industry. With a commitment to quality and innovation, Leshan has consistently delivered top-notch machinery that meets the evolving demands of the market. The company's dedication to research and development has positioned it as a pioneer in the field, offering machines that are both reliable and advanced.

The Need for Custom Solutions

In today's competitive market, businesses require products that stand out. Customization is key, allowing companies to differentiate themselves and meet specific consumer needs. This is particularly true in industries such as automotive, packaging, and consumer goods, where product design and functionality play crucial roles in consumer choice.

Leshan recognized this need early on and has focused on developing machinery that allows for high levels of customization. Their extrusion blow molding machines are designed to offer unparalleled flexibility, enabling manufacturers to produce a wide variety of shapes and sizes with precision.

Features of Leshan's Extrusion Blow Molding Machine

The innovative extrusion blow molding machine by Leshan boasts a range of features that set it apart from traditional models:

- Advanced Control Systems: The machine is equipped with state-of-the-art control systems that allow for precise adjustments and real-time monitoring. This ensures consistent quality and reduces the risk of defects.

- Energy Efficiency: Leshan's machine is designed to minimize energy consumption, making it both environmentally friendly and cost-effective. This is achieved through optimized heating systems and efficient motor designs.

- Versatility: Whether it's producing small containers or large automotive parts, the machine can handle a wide range of materials and sizes. This versatility is a significant advantage for manufacturers looking to diversify their product lines.

- Durability and Reliability: Constructed with high-quality materials, Leshan's machine is built to last. Its robust design ensures minimal downtime and maintenance, allowing for continuous production.

Applications Across Industries

The applications of Leshan's extrusion blow molding machine are vast, spanning multiple industries:

- Automotive: In the automotive industry, the machine is used to produce components such as fuel tanks, air ducts, and other complex parts that require precision and durability.

- Packaging: For packaging solutions, Leshan's machine can create bottles, containers, and jars of various shapes and sizes, catering to the needs of food, beverage, and cosmetic companies.

- Consumer Goods: The machine is also ideal for manufacturing household items, toys, and other consumer products that require intricate designs and robust construction.

Innovation at Leshan

Leshan's commitment to innovation is evident in its continuous efforts to improve and refine its blow molding technology. The company invests heavily in research and development, working closely with clients to understand their specific needs and challenges. This collaborative approach ensures that Leshan's machines are not only technologically advanced but also highly practical and user-friendly.

One of the key innovations in Leshan's extrusion blow molding machine is its ability to integrate with Industry 4.0 technologies. By incorporating IoT (Internet of Things) capabilities, the machine can communicate with other devices and systems, enabling seamless data exchange and enhanced automation. This connectivity allows for predictive maintenance, real-time performance monitoring, and improved overall efficiency.

Client Success Stories

Leshan's extrusion blow molding machine has been instrumental in helping clients achieve their manufacturing goals. Several success stories highlight the machine's impact across different sectors:

- Case Study 1: A leading automotive manufacturer was able to reduce production costs by 20% and increase output by 15% after implementing Leshan's machine. The precision and reliability of the machine allowed them to produce complex parts with minimal waste.

- Case Study 2: A packaging company specializing in eco-friendly solutions utilized Leshan's machine to create biodegradable containers. The machine's versatility and energy efficiency aligned perfectly with the company's sustainability goals.

- Case Study 3: A consumer goods manufacturer expanded its product line by introducing a range of custom-designed toys. Leshan's machine enabled them to experiment with different shapes and materials, resulting in a successful product launch.

Future Prospects

As the demand for customized solutions continues to grow, Leshan is poised to play a significant role in shaping the future of blow molding technology. The company's focus on innovation, quality, and customer satisfaction ensures that it remains a leader in the industry.

Looking ahead, Leshan plans to further enhance its extrusion blow molding machines by incorporating cutting-edge technologies such as artificial intelligence and machine learning. These advancements will enable even greater levels of automation and precision, offering clients unmatched capabilities in product design and manufacturing.

Conclusion

Leshan's innovative extrusion blow molding machine represents a significant advancement in the plastics manufacturing industry. With its focus on customization, efficiency, and reliability, the machine offers a comprehensive solution for businesses looking to stay competitive in a rapidly evolving market.

By continually pushing the boundaries of technology and working closely with clients, Leshan is not only meeting the current demands of the industry but also setting the stage for future innovations. As a result, Leshan remains a trusted partner for companies seeking to enhance their production capabilities and deliver exceptional products to their customers.

In summary, Leshan's extrusion blow molding machine is a testament to the company's dedication to excellence and innovation. Its ability to provide custom solutions across various industries makes it an invaluable asset for manufacturers worldwide. With a clear vision for the future, Leshan continues to lead the way in blow molding technology, ensuring that its clients are always at the forefront of the industry.