How EBM Machine Technology is Evolving

How EBM Machine Technology is Evolving

In the rapidly evolving world of manufacturing, extrusion blow molding (EBM) technology has emerged as a pivotal process for producing hollow plastic parts and containers. As industries demand more efficient, sustainable, and precise manufacturing solutions, companies like Leshan have been at the forefront, driving innovation in EBM machine technology. This article explores how Leshan, a renowned blow molding machine manufacturer, is redefining the landscape of EBM technology.

Understanding Extrusion Blow Molding (EBM) Technology

Extrusion blow molding is a manufacturing process used to create hollow plastic products. The process involves melting plastic and forming it into a parison — a tube-like piece of plastic with a hole in one end through which compressed air can pass. This parison is then clamped into a mold and inflated, taking the shape of the mold to form the final product.

EBM is particularly favored for its efficiency in producing complex shapes and its ability to handle a variety of materials, including polyethylene, polypropylene, and PVC. Its applications range from producing small bottles to large industrial containers, making it a versatile choice for manufacturers.

Leshan: A Pioneer in Blow Molding Machine Manufacturing

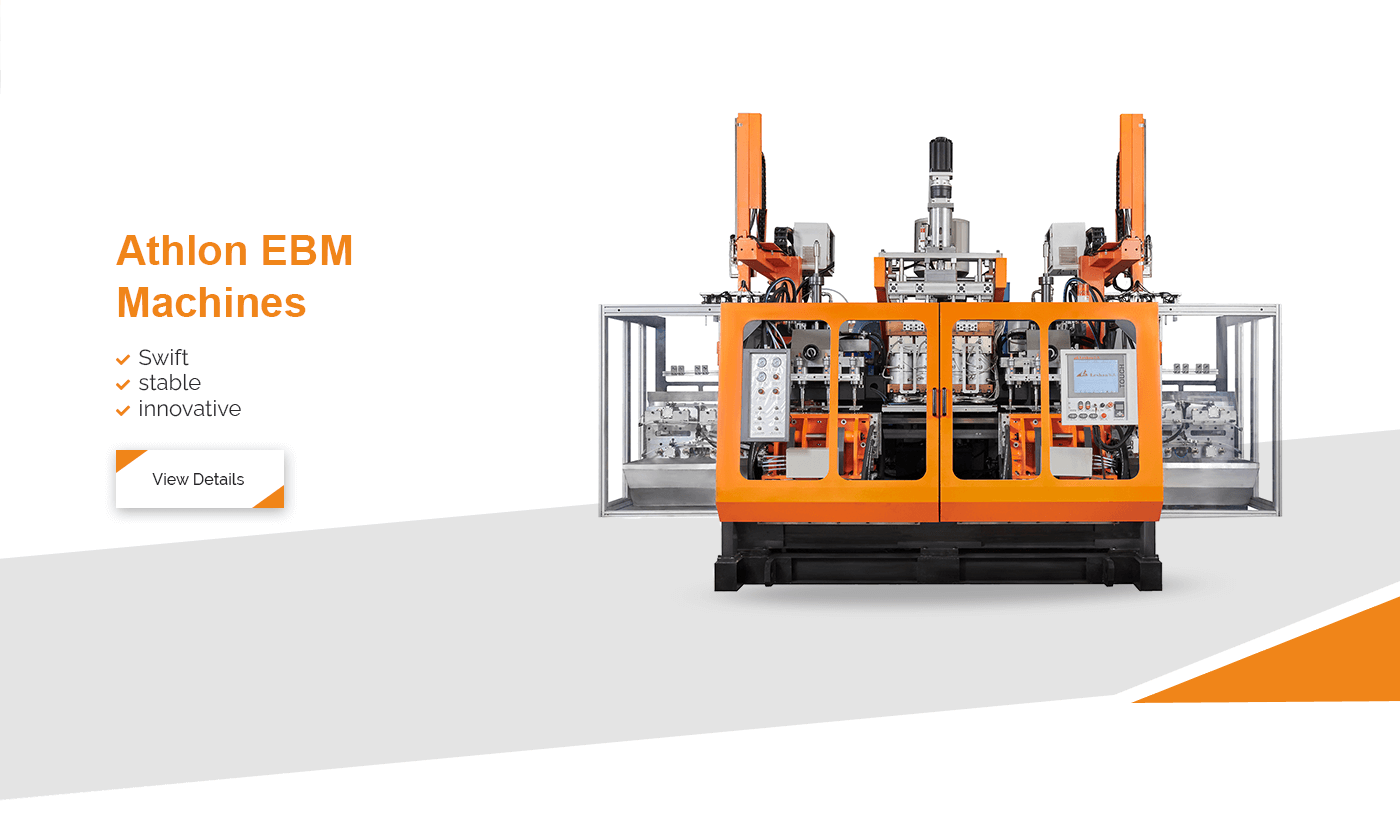

Leshan has established itself as a leader in the blow molding machine industry, known for its commitment to innovation and quality. With decades of experience, Leshan has continually pushed the boundaries of EBM technology, ensuring that their machines meet the ever-evolving needs of various industries.

One of Leshan's core strengths lies in its ability to integrate cutting-edge technology with practical manufacturing needs. This approach has enabled them to offer machines that are not only efficient but also sustainable and adaptable to future technological advancements.

Innovations in EBM Technology by Leshan

As the demand for more efficient production processes grows, Leshan has focused on several key areas to enhance their EBM machines:

- Energy Efficiency: Leshan's machines are designed to minimize energy consumption while maximizing output. This is achieved through advanced motor technology and optimized heating systems, which reduce the overall energy footprint of the production process.

- Precision and Control: The incorporation of advanced control systems allows for precise management of the molding process. This ensures that each product meets stringent quality standards, reducing waste and improving overall efficiency.

- Material Versatility: Leshan's EBM machines are capable of handling a wide range of materials, providing manufacturers with the flexibility to produce diverse products without needing multiple machines.

- Sustainability: With an increasing focus on environmental responsibility, Leshan has developed machines that support the use of recycled materials, helping manufacturers meet sustainability goals without compromising on quality.

The Role of Automation and AI in EBM Technology

Automation and artificial intelligence (AI) are transforming industries across the globe, and EBM technology is no exception. Leshan has embraced these advancements, incorporating them into their machines to enhance productivity and precision.

Automated systems in Leshan's EBM machines allow for real-time monitoring and adjustments, reducing the need for manual intervention. This not only speeds up the production process but also ensures consistent product quality. Furthermore, AI-driven analytics provide insights into machine performance and maintenance needs, allowing for proactive management and reduced downtime.

Case Studies: Leshan's Impact on Various Industries

Leshan's innovations in EBM technology have had a significant impact on numerous industries. Here are a few examples:

Packaging Industry

The packaging industry has greatly benefited from Leshan's EBM machines. With the ability to produce high-quality, lightweight containers, manufacturers can reduce material usage and transportation costs. Leshan's machines also support the use of biodegradable and recycled materials, aligning with the industry's sustainability goals.

Automotive Industry

In the automotive sector, Leshan's EBM technology is used to produce complex parts with high precision. The ability to create durable, lightweight components contributes to vehicle efficiency and performance. Leshan's focus on precision ensures that each part meets the stringent safety and quality standards of the automotive industry.

Consumer Goods

For consumer goods, Leshan's EBM machines offer the flexibility to produce a wide range of products, from household items to toys. The machines' versatility in handling different materials and producing intricate designs allows manufacturers to meet diverse consumer demands efficiently.

Challenges and Future Directions

Despite the advancements, the EBM industry faces several challenges. The need for continuous innovation to keep up with market demands, the integration of sustainable practices, and the management of production costs are ongoing concerns.

Leshan is actively addressing these challenges by investing in research and development. Future directions for Leshan include further integration of IoT technologies to enhance machine connectivity and data analytics, as well as the development of machines that can seamlessly integrate with Industry 4.0 environments.

The Importance of Collaboration and Partnerships

To stay ahead in the competitive landscape, Leshan emphasizes the importance of collaboration with industry partners and clients. By understanding the unique needs of each industry, Leshan can tailor their machines to provide optimal solutions.

Partnerships with material suppliers, technology developers, and research institutions also play a crucial role in driving innovation. These collaborations ensure that Leshan remains at the cutting edge of EBM technology, providing their clients with the most advanced and efficient machines available.

Conclusion

The evolution of EBM machine technology, spearheaded by companies like Leshan, is transforming the manufacturing landscape. Through relentless innovation and a commitment to quality, Leshan is setting new standards in the industry, offering solutions that are efficient, sustainable, and adaptable to future advancements.

As industries continue to evolve, the role of EBM technology will undoubtedly expand, offering new possibilities for manufacturers worldwide. With Leshan leading the charge, the future of blow molding looks promising, characterized by enhanced efficiency, precision, and sustainability.

In conclusion, Leshan's dedication to advancing EBM technology not only benefits their clients but also contributes to the broader goals of sustainable and efficient manufacturing. As they continue to innovate, Leshan remains a key player in shaping the future of the blow molding industry.