Durable PETG Bottle Blow Molding Machine for Extended Use

Durable PETG Bottle Blow Molding Machine for Extended Use

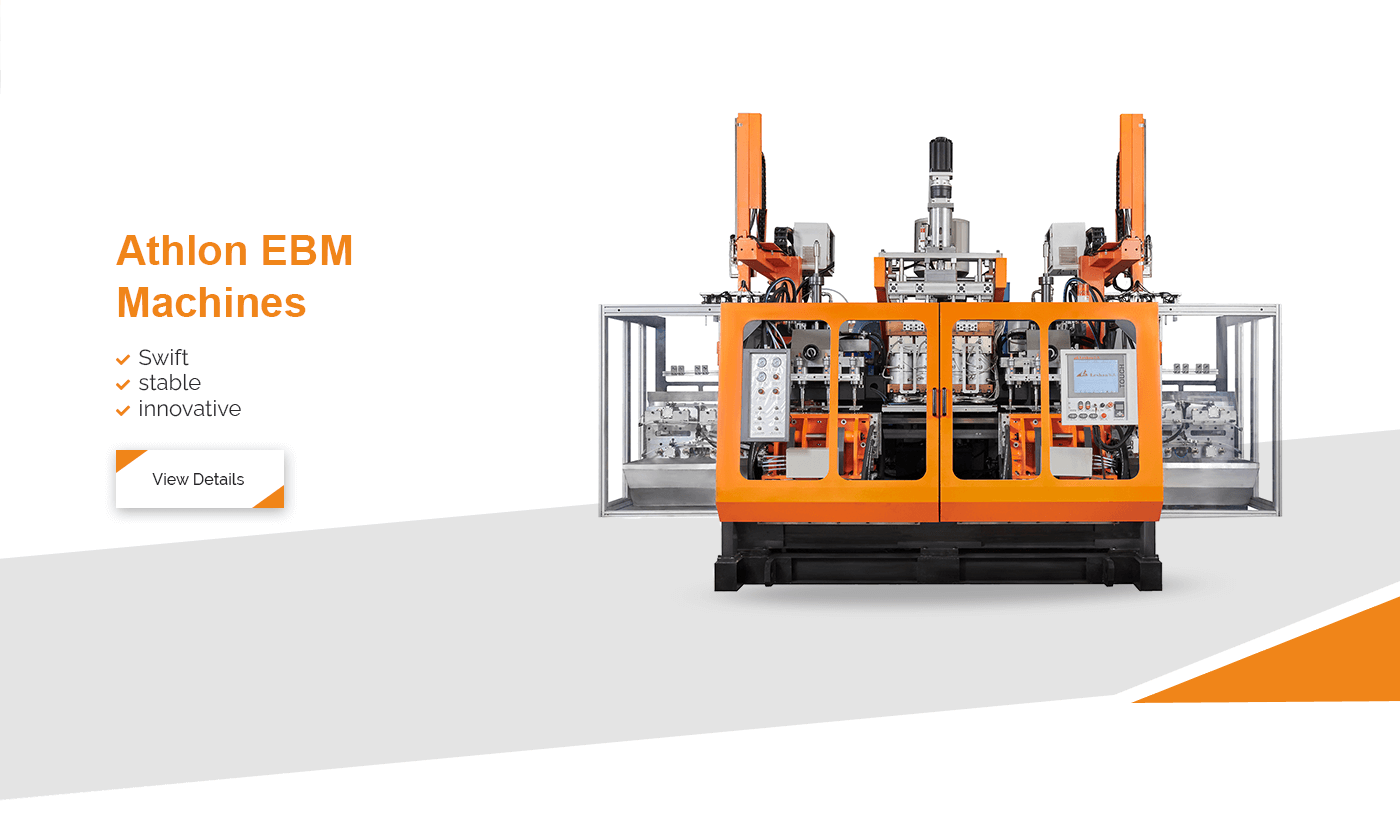

Leshan, a leading blow molding machine manufacturer, offers a detailed description of our durable PETG bottle blow molding machine, designed for extended use in various manufacturing environments. This article highlights the features, benefits, and technical specifications of our advanced blow molding technology.

Overview of PETG Bottle Blow Molding Machine

Definition and Process

The PETG (Polyethylene Terephthalate Glycol) bottle blow molding machine is designed to produce high-quality PETG bottles through the blow molding process. This process involves heating PETG preforms until they become malleable and then inflating them into molds to form bottles of various shapes and sizes.

Applications

Leshan's PETG bottle blow molding machines are widely used in industries such as food and beverage, cosmetics, pharmaceuticals, and household chemicals. These machines are ideal for manufacturing durable and transparent PETG bottles that meet industry standards.

Features of Leshan's PETG Bottle Blow Molding Machine

High Durability and Extended Use

Robust Construction

Our blow molding machines are built with high-quality materials and advanced engineering to ensure long-lasting durability. The robust construction is designed to withstand the rigors of continuous use in demanding manufacturing environments.

Advanced Technology

Leshan incorporates cutting-edge technology in our blow molding machines, ensuring efficient and precise bottle production. The machines are equipped with automated systems that optimize the molding process, reducing downtime and increasing productivity.

Versatility and Customization

OEM/ODM Services

We offer comprehensive OEM/ODM services to tailor our blow molding machines to meet specific customer requirements. This customization ensures that our machines can produce a wide range of bottle designs and sizes, providing flexibility for various applications.

R&D and Design Capabilities

Our strong R&D and design capabilities enable us to innovate and improve our blow molding technology continuously. Leshan's team of experts collaborates with clients to develop solutions that enhance performance and efficiency.

Superior Cost Performance

Efficiency and Productivity

Leshan's PETG bottle blow molding machines are designed for high efficiency and productivity. The automated systems and advanced features reduce production time and energy consumption, resulting in lower operational costs and better cost performance.

Minimal Maintenance

The durable construction and high-quality components of our blow molding machines ensure minimal maintenance requirements. This reduces downtime and maintenance costs, further enhancing the overall cost-effectiveness of our machines.

Technical Specifications

Machine Dimensions and Capacity

Leshan's PETG bottle blow molding machines come in various sizes and capacities to accommodate different production needs. Our machines are capable of producing bottles ranging from small 50ml containers to large 5-liter bottles, providing versatility for various manufacturing requirements.

Energy Efficiency

Our blow molding machines are designed with energy-efficient components and systems, ensuring that they operate with minimal energy consumption. This not only reduces operational costs but also aligns with sustainable manufacturing practices.

Advantages of Leshan's PETG Bottle Blow Molding Machine

Consistent Quality

Our blow molding machines ensure consistent bottle quality with precise control over the molding process. This consistency is crucial for maintaining product standards and meeting regulatory requirements.

Enhanced Flexibility

The ability to produce a wide range of bottle shapes and sizes provides manufacturers with the flexibility to meet changing market demands. Leshan's customization options further enhance this flexibility, making our machines suitable for diverse applications.

Reliable Supply and Support

As a trusted blow molding machine manufacturer, Leshan ensures reliable supply and comprehensive support for our customers. Our global network of distributors and agents guarantees timely delivery and expert assistance, wherever you are located.

Conclusion

Leshan's durable PETG bottle blow molding machines are designed for extended use and high performance in various manufacturing environments. With advanced technology, robust construction, and exceptional cost performance, our machines provide the ideal solution for producing high-quality PETG bottles.

For more information on our products and services, or to discuss your specific blow molding requirements, contact Leshan today. Let us be your reliable partner in providing high-quality blow molding solutions from China.