Difference Between Gradient Color and Plain Bottle Blow Molding Machines

Difference Between Gradient Color and Plain Bottle Blow Molding Machines

Blow molding technology has transformed the plastic packaging industry, allowing manufacturers to produce bottles of various shapes, sizes, and colors efficiently. Two popular types of blow molding machines are gradient color and plain bottle blow molding machines. At Leshan, a leading blow molding machine manufacturer, we understand the importance of choosing the right type of machine to meet your specific production needs. This article explores the key differences between gradient color and plain bottle blow molding machines, as well as their benefits and applications.

Table of Contents

- Introduction to Blow Molding Machines

- What Are Plain Bottle Blow Molding Machines?

- Understanding Gradient Color Blow Molding Machines

- Key Differences Between Gradient Color and Plain Bottle Blow Molding Machines

- Applications and Industries for Gradient Color and Plain Bottles

- Why Choose Leshan for Blow Molding Machines

- Conclusion

1. Introduction to Blow Molding Machines

Blow molding is a manufacturing process that shapes hollow plastic containers by inflating heated plastic within a mold. This technique is widely used for producing bottles and containers for various industries, such as food and beverage, pharmaceuticals, personal care, and household products. Blow molding machines come in different types and configurations to achieve specific design and color effects, including gradient color and plain bottle blow molding.

Leshan offers a range of blow molding machines tailored to meet different production needs, from standard plain bottles to innovative gradient designs that make products stand out on store shelves.

2. What Are Plain Bottle Blow Molding Machines?

Plain bottle blow molding machines are designed to produce bottles with a single, uniform color throughout the entire bottle. These machines are widely used for high-volume production of bottles where color consistency and simplicity are key. Plain bottles are common in various industries, especially where the focus is on functionality and durability rather than aesthetic appeal.

Advantages of Plain Bottle Blow Molding Machines:

- Cost-Effective Production: Plain bottles are easier to manufacture, requiring fewer color changes and reducing production time.

- High Efficiency: Plain bottle machines are highly efficient for high-volume runs, making them ideal for large-scale production.

- Consistency: The single-color approach ensures uniformity across all products, which is crucial for branding consistency.

- Versatility: These machines can handle a variety of colors, making it easy to switch between single-color options as needed.

3. Understanding Gradient Color Blow Molding Machines

Gradient color blow molding machines are specialized machines that allow for color transitions, creating bottles with multiple colors that blend seamlessly. This gradient effect is achieved by carefully controlling the color application within the mold, producing bottles with unique, eye-catching designs. Gradient color blow molding requires precise control and advanced technology, making it suitable for premium products and brands that value aesthetic appeal.

Advantages of Gradient Color Blow Molding Machines:

- Enhanced Visual Appeal: Gradient bottles offer a unique and attractive look, helping brands differentiate themselves in a competitive market.

- Branding Opportunities: With the option to create distinctive color transitions, companies can reinforce their branding with unique packaging.

- Customization Flexibility: Gradient blow molding machines allow manufacturers to experiment with various color combinations, creating a customized, premium feel.

- Higher Perceived Value: Products with gradient colors often appeal to premium markets, as they communicate quality and exclusivity.

4. Key Differences Between Gradient Color and Plain Bottle Blow Molding Machines

While both types of blow molding machines produce high-quality bottles, they serve different purposes and offer unique benefits. Here’s a breakdown of the main differences:

| Feature | Plain Bottle Blow Molding Machines | Gradient Color Blow Molding Machines |

|---|---|---|

| Color Application | Single, uniform color | Multiple colors with seamless transitions |

| Complexity | Relatively simple operation | More complex, requires advanced color control |

| Production Cost | Lower cost due to simpler color management | Higher cost due to additional color control |

| Efficiency | High efficiency for large volumes | Slightly lower efficiency due to color transitions |

| Brand Appeal | Standard, functional look | Enhanced aesthetic appeal, premium appearance |

| Customization Options | Limited to single colors | High customization with various color gradients |

| Application | Suitable for high-volume, functional products | Ideal for premium or luxury products |

Production Complexity

Gradient color blow molding requires precise control to achieve a smooth color transition, adding complexity to the production process. Plain bottle machines, on the other hand, apply a single color uniformly, making the production process simpler and faster.

Cost Considerations

Gradient color machines may have higher operating costs due to the additional color components and control systems required. However, the unique visual appeal of gradient bottles often justifies the cost for brands aiming to capture a premium market.

Branding and Marketing Value

Plain bottle machines are ideal for brands focusing on simplicity and functionality, while gradient color blow molding machines cater to brands that prioritize aesthetics and seek to stand out in a crowded marketplace.

5. Applications and Industries for Gradient Color and Plain Bottles

Both gradient color and plain bottles are essential across multiple industries, though each has unique applications based on its visual appeal and production cost.

Plain Bottle Applications

Plain bottles are commonly used for everyday consumer products where branding simplicity is valued. Examples include:

- Food and Beverage: Plain water bottles, juice containers, and milk jugs.

- Personal Care: Shampoo, conditioner, and lotion bottles.

- Household Products: Cleaning solutions, detergents, and disinfectants.

Gradient Color Bottle Applications

Gradient bottles cater to markets where visual appeal is crucial. Industries where gradient bottles are popular include:

- Cosmetics and Skincare: Premium packaging for products like perfumes, lotions, and facial mists.

- Alcoholic Beverages: Distinctive bottle designs for spirits and specialty beverages.

- Health and Wellness: Attractive packaging for vitamins, supplements, and organic products.

At Leshan, we work with clients across these industries to provide blow molding machines that meet their design, functionality, and branding needs.

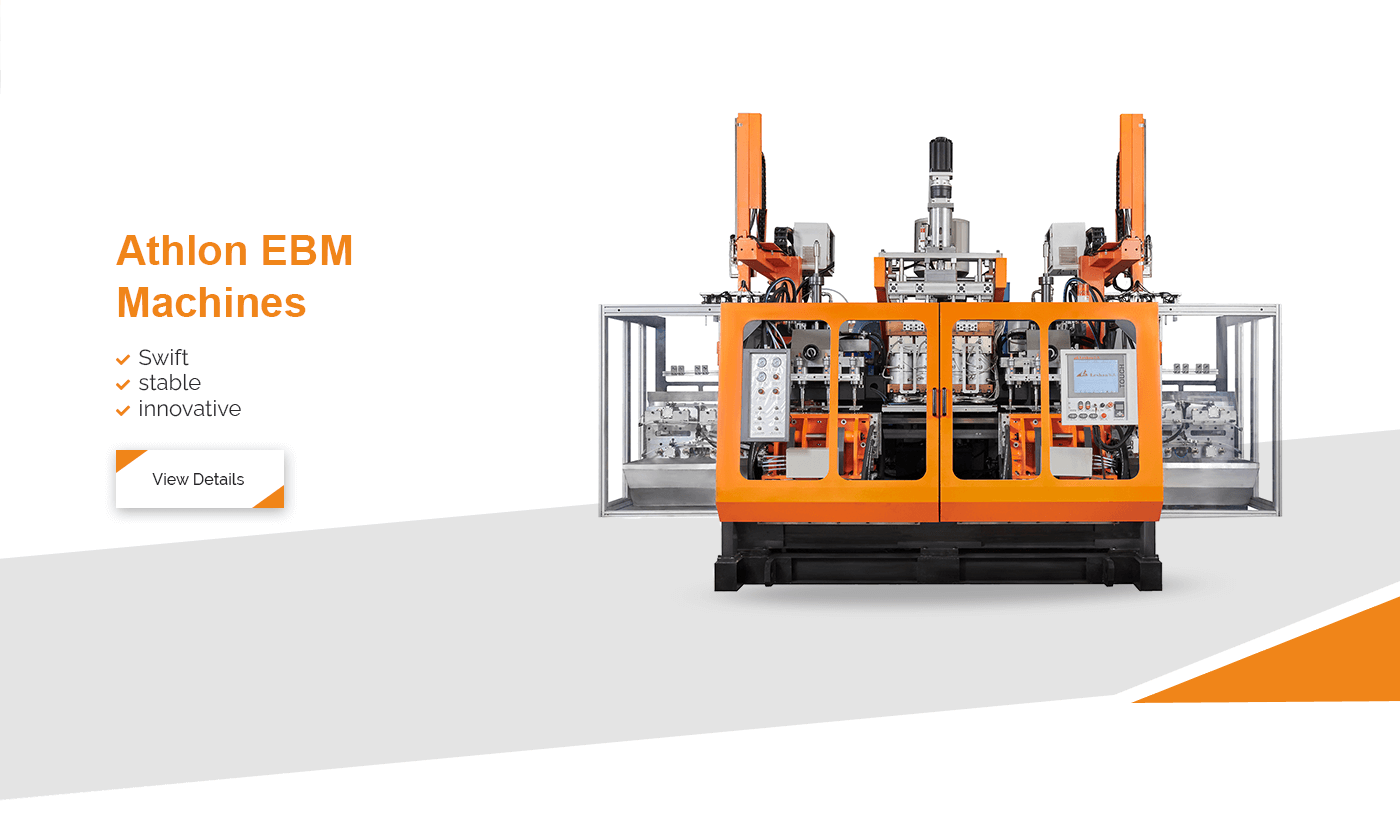

6. Why Choose Leshan for Blow Molding Machines

Choosing the right blow molding machine manufacturer is essential for producing high-quality bottles that meet both functionality and aesthetic standards. Leshan is a trusted provider of blow molding machines, with a commitment to quality, innovation, and customer satisfaction. Here’s why Leshan stands out as a blow molding machine manufacturer:

- Expertise in Advanced Blow Molding Technologies: With years of experience, Leshan provides machines that are optimized for both gradient color and plain bottle production, ensuring consistency and quality.

- Custom Solutions for Unique Needs: We offer customizable blow molding machines that cater to specific design and color requirements, helping brands achieve their desired look.

- High Precision and Control: Leshan’s machines are equipped with advanced technology that provides precise control over color application and bottle shape, ensuring premium quality for gradient bottles.

- Robust Build and Reliability: Built with durable materials and top-tier components, Leshan blow molding machines are designed for long-lasting performance, minimizing maintenance and downtime.

- Comprehensive Support and Training: Leshan provides extensive training and ongoing support, helping clients optimize machine operation and maximize production efficiency.

7. Conclusion

When it comes to producing high-quality plastic bottles, selecting the right blow molding machine is crucial. Plain bottle blow molding machines are ideal for high-volume production of single-color bottles that prioritize functionality, while gradient color blow molding machines offer unique visual appeal for brands aiming to differentiate themselves. Both types of machines have their own set of advantages, and at Leshan, we provide high-quality, reliable machines to meet the diverse needs of our clients.

Whether you’re looking for efficient production of plain bottles or want to explore the aesthetic possibilities of gradient colors, Leshan has the blow molding solutions to elevate your packaging. Contact Leshan today to learn more about our range of blow molding machines and find the perfect solution for your manufacturing needs.