Difference Between EBM and IBM Blow Molding Machines

Difference Between EBM and IBM Blow Molding Machines

Blow molding is a widely used manufacturing process for producing hollow plastic parts, such as bottles, containers, and other packaging products. Among the various types of blow molding techniques, Extrusion Blow Molding (EBM) and Injection Blow Molding (IBM) are two of the most prominent methods. Both processes are highly efficient and suitable for different applications, but they differ in terms of operation, design, and end product characteristics.

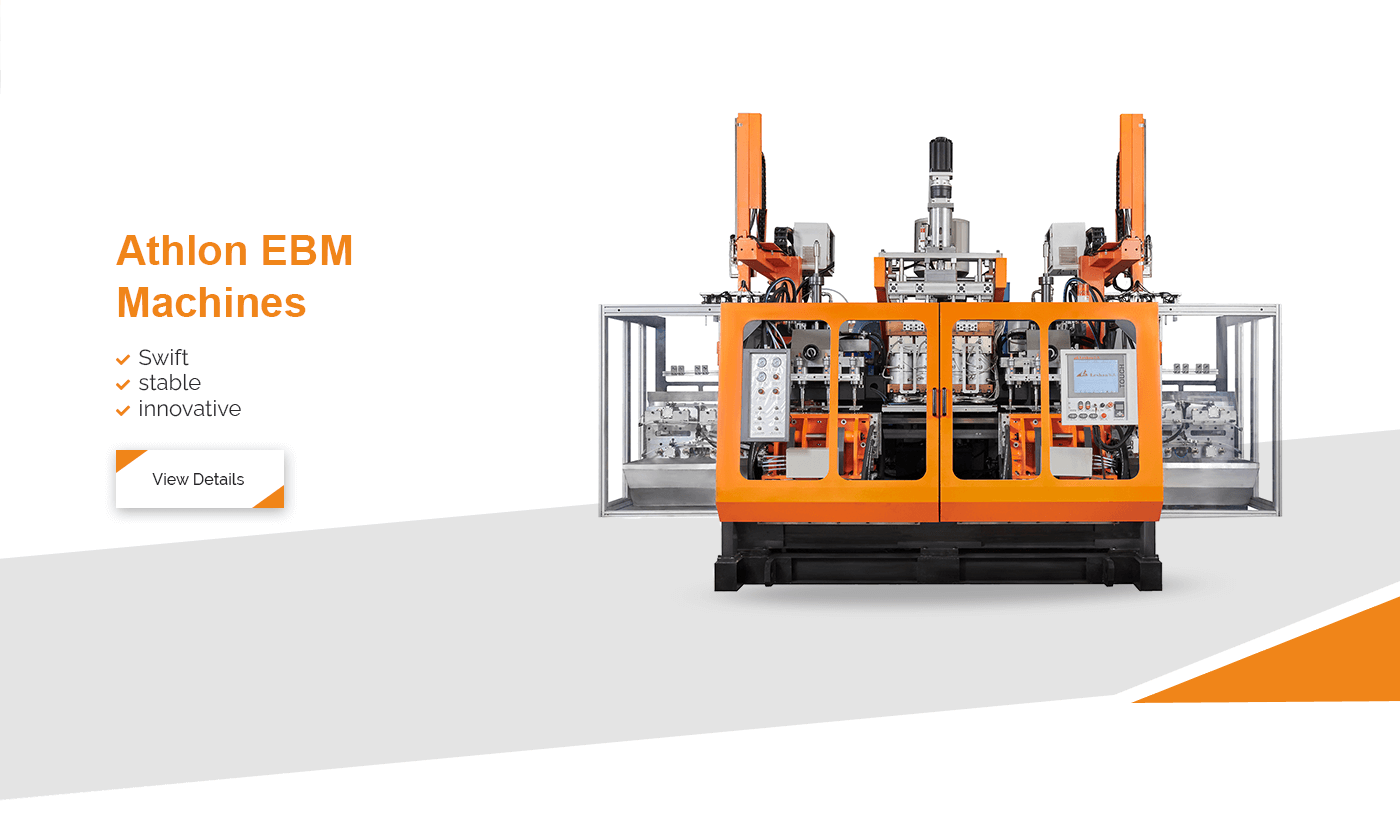

In this article, we will explore the differences between EBM and IBM blow molding machines, their advantages, and their applications. Leshan, a leading blow molding machine manufacturer, provides a wide range of machines for both EBM and IBM processes. Understanding these differences can help manufacturers choose the right machine for their specific production needs.

What is Extrusion Blow Molding (EBM)?

Extrusion Blow Molding (EBM) is a process where a molten plastic parison (a hollow tube) is extruded from an extruder. The parison is then enclosed in a mold, and air is blown into it, causing the plastic to expand and take the shape of the mold. Once cooled, the mold opens, and the final product is ejected.

EBM is commonly used for producing larger, hollow objects such as detergent bottles, automotive fuel tanks, and industrial drums. It is particularly suited for products that require uniform wall thickness and high durability.

Key Features of EBM Machines:

- Uses a continuous extrusion process to create the parison.

- Capable of producing large and complex shapes.

- Highly versatile in terms of material compatibility.

- Typically requires secondary operations like trimming to remove excess material.

What is Injection Blow Molding (IBM)?

Injection Blow Molding (IBM) is a process that combines injection molding and blow molding techniques. In this method, a preform is first created using injection molding. The preform is then transferred to a blow mold, where air is blown into it to form the final shape. IBM is ideal for producing small, precise, and high-quality containers, such as pharmaceutical bottles and cosmetic packaging.

IBM machines are known for their precision and ability to produce products with excellent surface finish and tight tolerances. Leshan's IBM machines are designed to deliver consistent performance and high-quality output.

Key Features of IBM Machines:

- Uses a preform created through injection molding.

- Produces products with high accuracy and superior surface finish.

- Ideal for small to medium-sized containers.

- Limited in terms of producing large or complex shapes.

Comparison Between EBM and IBM Machines

While both EBM and IBM machines are used for blow molding, they differ significantly in terms of process, applications, and advantages. Here’s a detailed comparison:

| Aspect | Extrusion Blow Molding (EBM) | Injection Blow Molding (IBM) |

|---|---|---|

| Process | Extrudes a molten parison and blows it into the mold. | Uses a preform created by injection molding, which is then blown into the mold. |

| Product Size | Suitable for large and complex shapes. | Best for small to medium-sized containers. |

| Precision | Moderate precision; may require post-processing. | High precision with excellent surface finish. |

| Material Usage | May result in material wastage due to trimming. | Efficient material usage with minimal waste. |

| Applications | Used for industrial drums, automotive fuel tanks, and large bottles. | Ideal for pharmaceutical, cosmetic, and food-grade containers. |

Advantages of EBM Machines

EBM machines offer several advantages that make them suitable for specific applications:

- Ability to produce large and complex parts.

- Flexibility in material selection, including HDPE, LDPE, and PP.

- Cost-effective for high-volume production of simple designs.

- Can produce multi-layered products for enhanced durability.

Advantages of IBM Machines

IBM machines are preferred for applications that require precision and high-quality finishes:

- Produces containers with tight tolerances and excellent surface finish.

- Efficient material usage with minimal waste.

- Capable of producing lightweight yet durable parts.

- Ideal for applications requiring strict hygiene standards, such as medical and pharmaceutical packaging.

Why Choose Leshan for Blow Molding Machines?

Leshan is a globally recognized manufacturer of high-quality blow molding machines. With decades of experience and a commitment to innovation, Leshan offers a comprehensive range of EBM and IBM machines to meet diverse manufacturing needs. Here’s why you should consider Leshan for your blow molding requirements:

1. Advanced Technology

Leshan’s machines are equipped with cutting-edge technology to ensure precision, efficiency, and reliability. Whether you need an EBM or IBM machine, Leshan provides solutions that are tailored to your production goals.

2. Customization Options

Every manufacturing process is unique, and Leshan understands this. The company offers customizable machines that can be adapted to specific product designs, materials, and production volumes.

3. Robust After-Sales Support

With a dedicated team of experts, Leshan provides comprehensive after-sales support, including installation, training, and maintenance services. This ensures that your machines operate at peak performance for years to come.

4. Commitment to Sustainability

Leshan is committed to sustainable manufacturing practices. Their machines are designed to minimize energy consumption and material waste, helping manufacturers reduce their environmental footprint.

Conclusion

Choosing between EBM and IBM blow molding machines depends on your specific production requirements. EBM machines are ideal for large and complex products, while IBM machines excel in producing small, precise, and high-quality containers. Leshan, as a leading blow molding machine manufacturer, offers state-of-the-art solutions for both processes, ensuring that you get the best machine for your needs.

By understanding the differences between EBM and IBM machines, you can make an informed decision that aligns with your manufacturing goals. Whether you’re in the automotive, pharmaceutical, or packaging industry, Leshan has the expertise and technology to help you succeed.

If you’re looking for reliable and efficient blow molding machines, contact Leshan today to learn more about their products and services. Their team of experts is ready to assist you in finding the perfect solution for your production needs.

Tags:blow molding machine application,High-Power EBM Complete Machine,blow molding machine