Can Multi Layers Blow Molding Machine Improve Product Quality

Can Multi Layers Blow Molding Machine Improve Product Quality

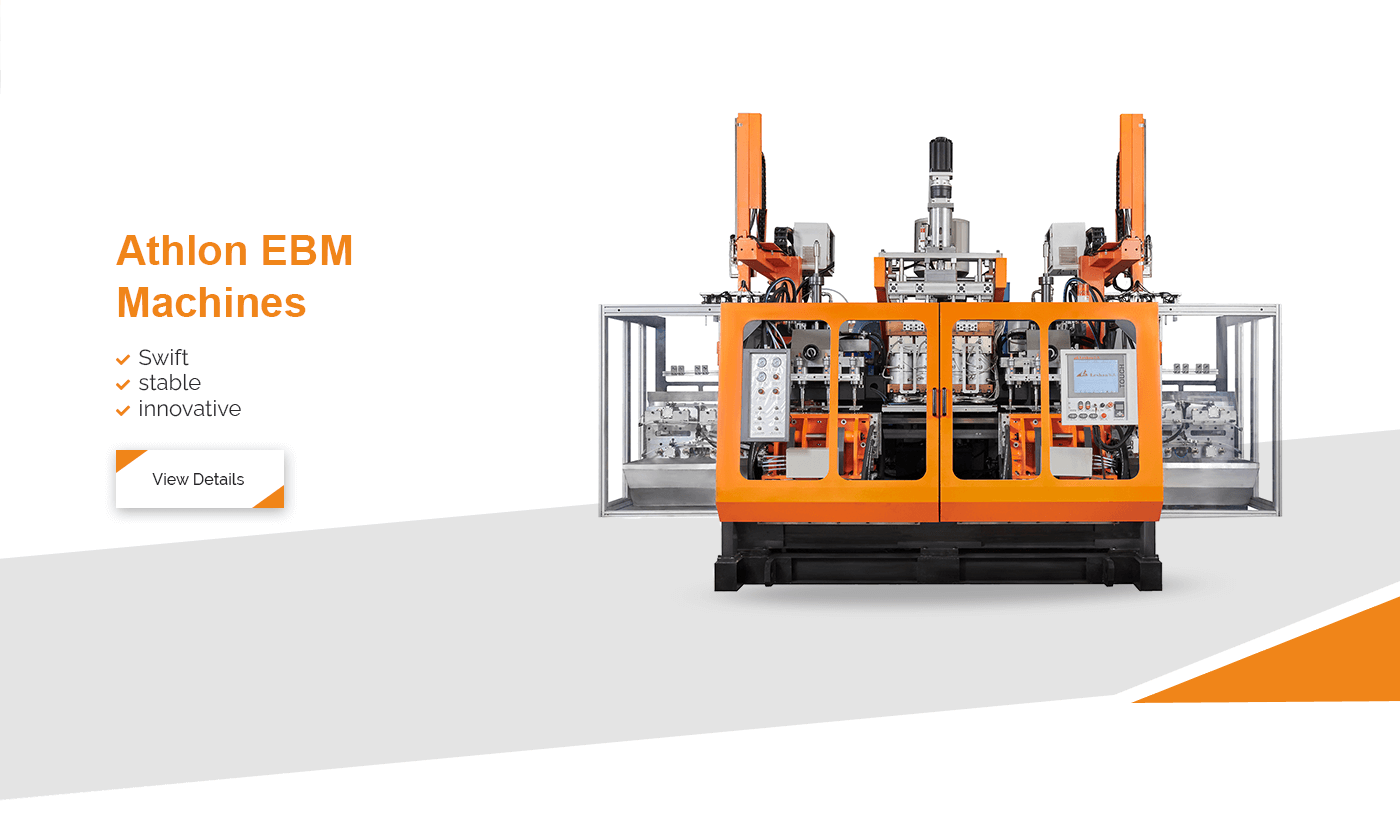

In the competitive world of manufacturing, product quality is paramount. Companies are constantly seeking innovative ways to improve their products and stand out in the market. One such innovation in the realm of plastic manufacturing is the multi-layer blow molding machine. As a leading blow molding machine manufacturer, Leshan is at the forefront of this technological advancement, providing solutions that enhance product quality and manufacturing efficiency.

Understanding Multi-Layer Blow Molding

Blow molding is a manufacturing process used to create hollow plastic parts. It involves inflating a heated plastic tube until it fills a mold and forms the desired shape. Traditional single-layer blow molding machines have been effective for many applications, but the advent of multi-layer blow molding technology has taken product quality to new heights.

Multi-layer blow molding involves the use of multiple layers of plastic to create a single product. This technique allows manufacturers to combine different types of plastics, each with its own unique properties, into a single product. The result is a product that benefits from the strengths of each material, such as enhanced strength, improved barrier properties, and increased durability.

The Role of Leshan in Multi-Layer Blow Molding

Leshan, a renowned blow molding machine manufacturer, has been a pioneer in the development and implementation of multi-layer blow molding technology. With years of experience and a commitment to innovation, Leshan has developed machines that are not only efficient but also capable of producing high-quality products consistently.

At Leshan, the focus is on creating machines that are easy to operate, maintain, and integrate into existing production lines. The company's multi-layer blow molding machines are designed to meet the diverse needs of various industries, from automotive to packaging, ensuring that each product is of the highest quality.

Advantages of Multi-Layer Blow Molding Machines

There are several advantages to using multi-layer blow molding machines, particularly those manufactured by Leshan. These advantages include:

- Improved Barrier Properties: By combining different materials, multi-layer blow molding machines can produce products with superior barrier properties, making them ideal for packaging applications where product preservation is critical.

- Enhanced Strength and Durability: Products made with multi-layer blow molding are typically stronger and more durable than their single-layer counterparts. This is because the layers can be tailored to provide additional strength where needed.

- Cost Efficiency: Although the initial investment in multi-layer blow molding machines may be higher, the long-term cost savings from reduced material usage and improved product quality can be significant.

- Customization: Multi-layer blow molding allows for greater customization in product design, enabling manufacturers to create products that meet specific customer requirements and stand out in the market.

Applications of Multi-Layer Blow Molding

Multi-layer blow molding is used in a wide range of applications, thanks to its versatility and the superior quality of the products it produces. Some of the most common applications include:

- Automotive Industry: In the automotive industry, multi-layer blow molding is used to produce fuel tanks, air ducts, and other components that require high strength and excellent barrier properties.

- Packaging Industry: The packaging industry benefits significantly from multi-layer blow molding, particularly for products that require extended shelf life, such as food and beverage containers.

- Consumer Goods: Multi-layer blow molding is also used to create durable consumer goods, such as water bottles and sports equipment, where durability and performance are critical.

Challenges and Solutions in Multi-Layer Blow Molding

While multi-layer blow molding offers numerous benefits, it also presents certain challenges. One of the primary challenges is the complexity of the process, which requires precise control over temperature, pressure, and material flow. This complexity can lead to increased production costs and the need for skilled operators.

However, Leshan has addressed these challenges by developing advanced machines equipped with state-of-the-art control systems. These systems ensure that each layer is applied accurately and consistently, resulting in high-quality products with minimal waste.

The Future of Multi-Layer Blow Molding

The future of multi-layer blow molding looks promising, with ongoing advancements in technology and materials. As manufacturers continue to seek ways to improve product quality and reduce costs, multi-layer blow molding is likely to become even more prevalent across various industries.

Leshan is committed to leading the charge in this area, investing in research and development to create innovative solutions that meet the evolving needs of its customers. By staying at the cutting edge of technology, Leshan ensures that its customers can produce the highest quality products efficiently and cost-effectively.

Conclusion

In conclusion, multi-layer blow molding machines have the potential to significantly improve product quality across various industries. By leveraging the strengths of different materials, manufacturers can create products that are stronger, more durable, and better suited to their intended applications.

Leshan, as a leading blow molding machine manufacturer, is dedicated to providing top-of-the-line multi-layer blow molding machines that help its customers achieve their quality and efficiency goals. With a focus on innovation and customer satisfaction, Leshan is poised to remain a leader in the blow molding industry for years to come.

As the demand for high-quality, cost-effective products continues to grow, multi-layer blow molding will undoubtedly play a crucial role in meeting these demands. By choosing Leshan's multi-layer blow molding machines, manufacturers can ensure that they are well-equipped to produce superior products that meet the needs of today's discerning consumers.