Are HDPE Bottle Blow Molding Machines Suitable for All Plastic Types

Are HDPE Bottle Blow Molding Machines Suitable for All Plastic Types

High-Density Polyethylene (HDPE) bottle blow molding machines have become a cornerstone in the plastic manufacturing industry, offering efficiency, durability, and versatility. Leshan, a leading blow molding machine manufacturer, has been at the forefront of developing advanced technologies to cater to the growing demand for plastic bottle production. However, a common question arises: Are HDPE bottle blow molding machines suitable for all plastic types?

In this article, we will delve into the capabilities and limitations of HDPE blow molding machines, explore their compatibility with various plastic types, and highlight why Leshan's innovative solutions are a trusted choice for manufacturers worldwide. By the end, you’ll have a clear understanding of whether these machines are the right fit for your production needs.

Understanding HDPE Bottle Blow Molding Machines

HDPE bottle blow molding machines are specifically designed to produce plastic bottles using high-density polyethylene. HDPE is a thermoplastic polymer widely recognized for its strength, durability, and resistance to chemicals. These machines utilize a blow molding process, which involves melting the plastic, forming it into a preform or parison, and then inflating it within a mold to create the desired bottle shape.

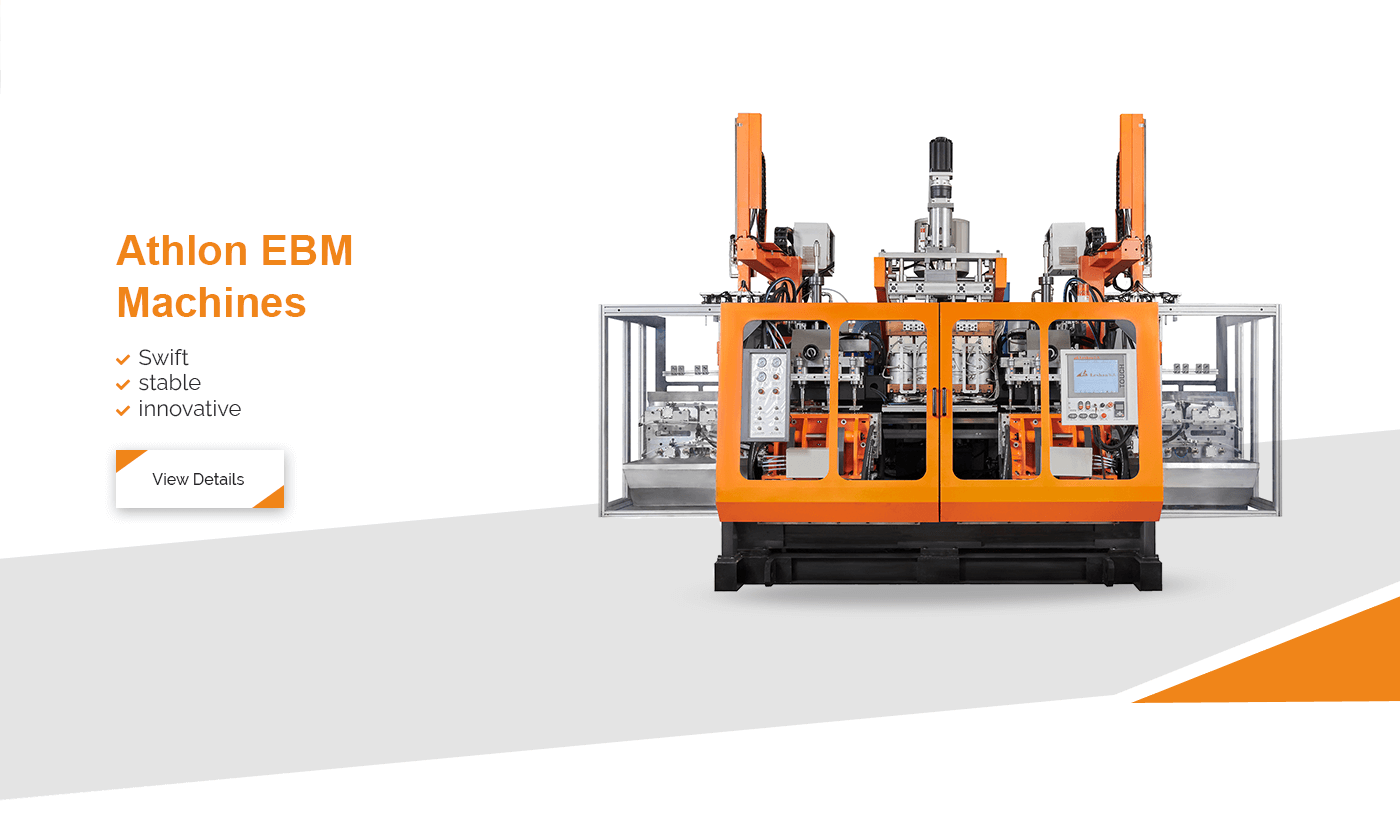

Blow molding machines come in various configurations, including extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM). Leshan specializes in manufacturing state-of-the-art machines that cater to diverse production requirements, ensuring high precision and efficiency in bottle manufacturing.

Key Features of Leshan's HDPE Blow Molding Machines

- High Efficiency: Leshan's machines are engineered for continuous operation, ensuring consistent production output.

- Energy Saving: Advanced energy-efficient designs help reduce operational costs.

- Customizability: Machines can be tailored to produce bottles of various shapes, sizes, and capacities.

- Durability: Built with high-quality materials, Leshan's machines offer long-term reliability.

- User-Friendly Operation: Intuitive interfaces and automated controls simplify the manufacturing process.

While HDPE blow molding machines are optimized for HDPE materials, their suitability for other plastic types depends on several factors, which we will discuss in the following sections.

Compatibility of HDPE Blow Molding Machines with Other Plastics

HDPE blow molding machines are primarily designed for processing HDPE materials. However, their compatibility with other plastic types depends on the physical and chemical properties of the material. Below, we explore the compatibility of these machines with commonly used plastics:

1. Polyethylene (PE)

HDPE is a type of polyethylene, so these machines are inherently compatible with other forms of PE, such as Low-Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE). However, adjustments to temperature and pressure settings may be required to accommodate the different melting points and viscosities of these materials.

2. Polypropylene (PP)

Polypropylene is another thermoplastic commonly used in bottle production. While HDPE blow molding machines can process PP, modifications to the machine’s settings and components may be necessary to handle the material’s higher melting point and different flow characteristics. Leshan offers customization options to ensure compatibility with PP materials.

3. Polyethylene Terephthalate (PET)

PET is widely used for producing clear and lightweight bottles, particularly in the beverage industry. However, PET requires a stretch blow molding process, which differs from the traditional HDPE blow molding process. Leshan manufactures specialized PET blow molding machines to cater to this specific need, ensuring optimal performance and quality.

4. Polyvinyl Chloride (PVC)

PVC is less commonly used in blow molding due to its environmental concerns and processing challenges. While HDPE machines can technically process PVC, it is not recommended due to the material’s release of corrosive gases during melting, which can damage the machine and pose health risks.

5. Other Plastics

Other plastics, such as polystyrene (PS) and acrylonitrile butadiene styrene (ABS), are not typically used in blow molding applications. These materials have different processing requirements and are better suited for injection molding or other manufacturing methods.

Factors to Consider When Using HDPE Blow Molding Machines for Other Plastics

While HDPE blow molding machines offer versatility, manufacturers need to consider the following factors when processing other plastics:

- Material Properties: The melting point, viscosity, and flow characteristics of the plastic must align with the machine’s capabilities.

- Machine Adjustments: Temperature, pressure, and cooling settings may need to be adjusted to accommodate different materials.

- Mold Design: The mold must be compatible with the material to ensure proper shaping and cooling.

- Environmental Impact: Some plastics, such as PVC, may release harmful gases during processing, requiring additional safety measures.

Leshan's team of experts provides comprehensive support to help manufacturers optimize their machines for various materials, ensuring seamless production and high-quality output.

Why Choose Leshan for Your Blow Molding Needs?

Leshan has established itself as a trusted name in the blow molding industry, offering cutting-edge solutions that cater to diverse manufacturing requirements. Here are some reasons why Leshan stands out:

1. Innovative Technology

Leshan invests heavily in research and development to stay ahead of industry trends. Their machines are equipped with the latest technology to ensure precision, efficiency, and sustainability.

2. Custom Solutions

Understanding that every manufacturer has unique needs, Leshan offers customized machines and molds to meet specific production goals.

3. Global Support

With a strong global presence, Leshan provides comprehensive after-sales support, including installation, training, and maintenance services.

4. Commitment to Quality

Leshan’s machines are built to last, using high-quality materials and rigorous quality control processes to ensure reliable performance.

Conclusion

HDPE bottle blow molding machines are highly efficient and versatile, making them an excellent choice for manufacturing HDPE bottles. While they can process other plastics, their suitability depends on the material’s properties and the machine’s configuration. Leshan, as a leading blow molding machine manufacturer, offers tailored solutions to meet diverse production needs, ensuring optimal performance and quality.

If you’re considering investing in a blow molding machine, it’s essential to evaluate your material requirements and consult with experts like Leshan to determine the best solution for your business. With their innovative technology, custom solutions, and global support, Leshan is well-equipped to help you achieve your manufacturing goals.

In conclusion, while HDPE blow molding machines are not universally suitable for all plastic types, their adaptability and Leshan’s expertise make them a valuable asset for any plastic manufacturing operation. Reach out to Leshan today to explore how their machines can transform your production process.

Tags:/mold,blow molding machine,blow molding machine manufacturer